- Green Products

- Waste Management Business

Waste Management Plan; A Complete Guide To Preparing A Waste Management Plan

Table of Contents

Introduction

Whether you are a school proprietor, a construction project manager or a curious student trying to learn how to write a waste management plan , this article is for you.

I have tried to keep It as concise as possible while still covering every aspect of a comprehensive waste management plan . You can implement this plan at any type of facility regardless of size. From a school to a construction site, to a hospital or a residential community. The same principles will apply regardless of size. Resources used for managing waste at each facility type may vary in terms of equipment, waste bins, personnel requirement but the steps remain the same.

Waste Management Strategy

The objective of a waste management plan is to plan on how waste generated from a facility can be managed efficiently to maximise recovery of value from waste and minimise waste disposal at the landfill.

A good waste management strategy is one that starts with identifying ways to minimise waste before the need to dispose of them even arises. It also involves engaging all the stakeholders involved in the value chain for waste generation and disposal to ensure that everyone plays a part in sustainable management of waste generated from their facility.

A good waste management strategy is one that ensures timely and efficient removal of all waste streams generated from a facility with optimal resource recovery through recycling in a safe and professional manner in compliance with applicable local regulations.

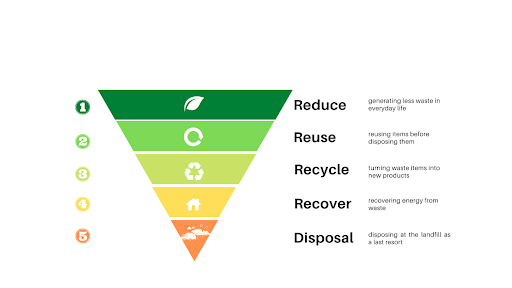

To achieve this, the waste management strategy should be focused around the 5-step hierarchy for sustainable waste management as detailed in the figure below.

Communication Strategy

To maximise waste diversion from the landfill and to optimise resource recovery from waste, it is essential to schedule training programs and awareness campaigns for all stakeholders involved on a regular basis.

To achieve this, focus on communicating the right message to all stakeholders. Keep it simple. Share simple guidelines on how they can manage the waste they generated in their immediate environment. This should include guidelines on how they can minimise waste generation from their activities in the first place, what to do with each waste stream, where to dispose of them and how to dispose of them properly to improve recycling.

To be effective ensure all stakeholders are involved in the early stage to get buy-in and have them play their part in the successful implementation of the plan.

- Encourage residents, staff and the management of the facility to become proactive & involved stakeholders in the planning process for the recycling initiative to ensure successful implementation.

- Communicate the plan via channels that would ensure the key message gets to everyone. Use emails, chat groups, notice boards, elevators, and other public spaces to ensure that residents and visitors are educated on the guidelines for sustainable waste management and recycling initiatives introduced as part of the waste management plan.

- Carry out public awareness/training campaigns on a scheduled basis to engage, inform and encourage participation within the facility.

- Monitor progress regularly and explore opportunities to improve and increase output from the program.

The overall objectives of the communication strategy should be:

- To attain a positive behaviour change among residents and all stakeholders with respect to waste management and caring for our environment.

- To display the importance and commitment to more sustainable and efficient use of resources across the facility.

- To maximise waste diversion from the landfill by optimising recycling of all recyclable waste streams generated from the facility.

Waste Management Training and Awareness Program

To achieve the waste minimization and recycling goals of a waste management plan, a three phased training and awareness program should be implemented to ensure that all stakeholders are captured, and key messages are delivered to achieve better results. These approaches are;

- Scheduled period awareness sessions with residents and operational staff at the facility to educate them on proper waste management and recycling techniques. You should cover the following topics during the session.

- Waste Stream Definition and Categorization

- Stakeholder Involvement

- Basic Waste Disposal Procedures and Waste Handling Techniques

- Waste Reduction Techniques

- Waste Reuse Techniques

- Waste Segregation Techniques

- Resource Conservation at Work

- Hygiene Guidelines for Waste Management

2. Awareness campaigns to mark events like World Environment Day , Earth Day , etc. This helps highlight the significance of their role in contributing to a greener world through sustainable waste management.

3. Awareness by visualization through designing and placement of awareness posters/boards around the facility to further educate and remind client staff on proper waste management and recycling techniques.

Implementation

Once the strategy and communication plan are in place, the next step is outlining how the waste management plan will be implemented. The first step towards implementing a waste management plan is to understand the types of waste generated from a facility or community. As you can imagine the waste composition could vary significantly from one type of facility to another. For example, a hotel would have a high composition of food waste coming from the different kitchens in a hotel that cater to restaurant and hotel guests. A construction project site on other hand would have a high proportion of concrete waste or metal scrap coming from the construction activities.

For these reasons, a crucial first step is to conduct a waste audit to fully understand the types of waste, sources, quantities, etc. and tailor the waste management plan for managing the waste streams efficiently.

Waste Audit

A waste audit is a method to identify the types of waste produced from a facility and how much of it there is. It can help you plan on how to reduce waste. It can also show you where recycling bins need to be placed or what guide you on other resources you might need to encourage sustainable waste management at a facility.

Key insights you can gain from a waste audit are.

- Type of waste generated

- Sources of waste generated

- Quantities of waste generated

The first step in conducting a waste audit is analysing what kind of items are being thrown away over time: how many paper towels were used at lunchtime? How many plastic containers were used for food storage?

Once you have completed the waste audit, collate the data, and analyse it for insights. Act based on your findings. Based on this information you’ve gathered, you can plan better on how to minimise waste generations, store waste efficiently, and encourage reuse/recycling of waste. A sample waste management audit template is provided in appendix 1. You can adapt this to suit your facility.

Goal Setting, Waste Management Training and Awareness Campaigns

Now that you are equipped with data and insights from the waste audit, the next step is to set goals for reducing and recycling waste.

Waste management training and awareness campaigns should be carried out for all stakeholders to get buy-in and educate them on the goals and the role they can play in contributing to achieving the goals.

- Start with a training needs analysis to understand how much people know and then tailor the awareness or training to address the gaps.

- Keep the training simple and deliver the content in a format that the target group will be more receptive to. Think infographics with dos and don’ts, short videos if you are targeting a young audience or simple notices in public areas. You can also consider email communication or a workshop if you can get a group together.

- Pay attention to getting the decision makers and leadership involved in the process. If there is buy-in from them, others will be more likely to participate as they see key stakeholders lead by example.

- This exercise should not be a one time activity, periodic reminders will be necessary to encourage people to make a habit out of participating in waste reduction and recycling activities.

Waste Management Segregation and Recycling Process

Here we outline how to manage the different waste streams generated across a facility. For each waste stream, I will outline steps for reducing waste, then reuse and finally recycling the waste to minimise the amount of waste that end up in the landfill.

Paper and Cardboard

Paper and cardboard are some of the most common recycling items found in places like homes, schools, offices, etc. These materials can be recycled into a variety of items, including new paper products, wallboard, insulation, and more. To reduce this type of waste, we can start by eliminating packaging as much as we can as this contributes a significant part of the paper and cardboard waste we generate.

To reduce paper waste, we can limit some communication to electronic circulation only to minimize paper waste generated from circulating them in print. We can also reuse the waste stream by reprinting on used paper, reusing cardboard packaging.

Here are tips on how to properly recycle paper and cardboard items:

- Identity sources of paper and cardboard waste

- Set aside a container or recycling box for collecting them

- Cardboard boxes should be flattened before being collected for recycling.

- Avoid throwing contaminated paper or cardboard in the recycling bin.

- Do not mix other waste items in the recycling bins for paper and cardboard as they can easily get contaminated. When there is a high level of contamination with paper and cardboard, recycling facilities reject them and they end up in landfills.

Paper Recycling Box and Recycling Cage for cardboard.

Organic waste (food waste).

Organic waste is mainly food waste like leftovers and the waste we generate when we are cooking like cuttings from vegetables and other food items. We can reduce this type of waste by planning our purchase to ensure we do not purchase excess food products that might end up as waste.

We can reduce the amount of organic waste that goes to the landfill by composting them for use as manure in our garden. For home use, there are simple composting bins you can purchase and use in your backyard to compost food waste. For bigger facilities like hotels and catering facilities, there are industrial composting units that can be procured to compost the large volumes of food produced in such facilities. Why is it important to divert food waste from the landfill you might ask. Here are some facts you might know;

- Food waste is a major source of methane gas. The methane produced by food waste in landfills is over one hundred times more potent than CO2 as an atmospheric greenhouse gas, making it a significant contributor to climate change.

- According to the EPA, food waste accounts for between 10-15% of all U.S. methane emissions and 9% of total U.S carbon dioxide emissions annually.

- Food waste is also a major contributor to pollution: it produces harmful substances like leachate (liquid that drains from landfills), odour, pests and vermin infestations (rats), groundwater contamination, littering issues.

- Food waste contributes significantly towards disease outbreaks in developing countries where there isn’t proper collection systems or infrastructure in place which leads people directly into contact with this material.

Home compost bin

Food waste composter.

Like other recyclable waste streams, you can collect metal scrap and cans in a separate bin for recycling. Metals are a valuable resource, and they can be recycled to create new products. Many metal items like aluminium can be recycled repeatedly, saving energy by reducing the quantity of raw materials needed to make new products.

Metal recycling saves 95% energy compared to manufacturing metal from fresh raw materials. So, it makes a lot of sense to recycle metals. Several types of metal items like aluminium, steel, copper, etc. can be recycled

This is the most recyclable waste we generate in terms of volume. A lot of the items we use at home and at workplaces come in plastic packaging. Plastic is a versatile material that can be used in many different ways. It’s inexpensive and easy to mass produce, which makes it ideal for use as containers, packaging and more. However, plastic is made from petroleum—a nonrenewable resource—so we must be careful not to waste it.

As before, we start with minimising plastic waste by reducing use of it in packaging. Next time you are at the grocery store, you can request to carry your items yourself if there are only a few of them instead of packing them in unnecessary layers of plastic bags. You can also go shopping with your own reusable bag, so you do not have a need for plastic bag packaging from the stores. Next, explore ways to reuse some of the plastic waste you generate. You can use them for storage or even gardening.

There are several types of plastics that can be recycled. Some of the common ones are.

- PET (Polyethylene Terephthalate); this is used for packaging products like water, carbonated drinks, body lotion, etc.

- HDPE (High Density Polyethylene); this is used for making products like shopping bags, waste bags, toys, etc.

- LDPE, (Low-Density Polyethylene); similar to HDPE, they are used for making product packaging, like bread and frozen food wraps, dry cleaning bags, coating of paper milk cartons, etc.

- PVC (Polyvinyl Chloride); this is used for making pipes and fittings, cables, etc.

- PP (Poly Polypropylene); these are for making hot food containers.

Depending on the space availability, you can sort your plastics by type for recycling or you can co-mingle them in one big and deposit them at the nearest recycling collection point near you.

Glass is a recyclable material. It can be recycled into new glass or used to make other products. When you recycle glass, you are taking a valuable resource and turning it into something new, which saves energy and material resources.

You can drop off your used glass for recycling at any collection point near you. There are many ways to recycle glass:

- You can separate your clear and coloured bottles from other recyclables by putting them in separate bins for collection at the school

- Clear glass bottles can be returned for cash at local stores that collect them, including grocery stores, pharmacies, convenience stores and more

- Some cities offer citizens free drop off locations for their empty beverage containers; check with your city’s website for more information on where these locations might be located

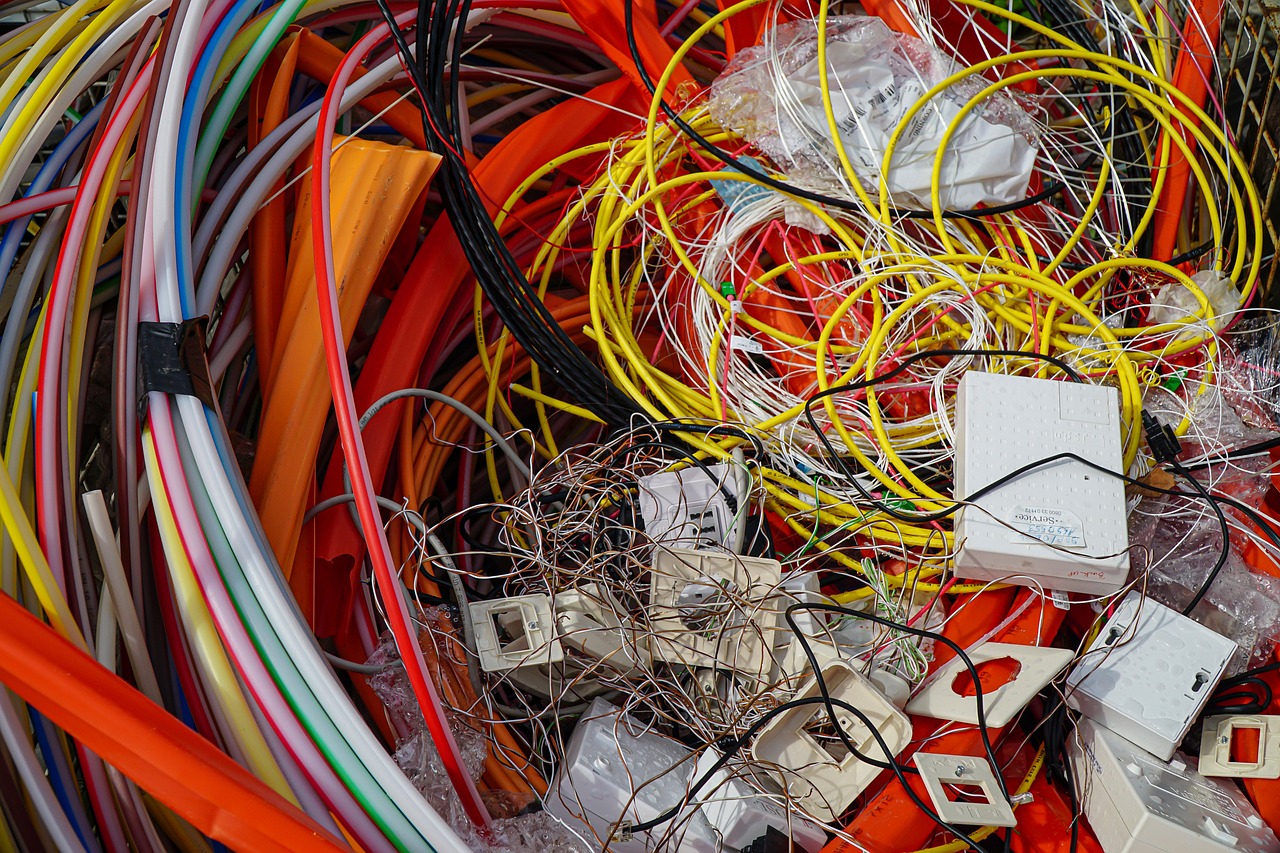

Electronics or e-waste

These are waste electronic items. We generate a lot more of these in recent times due to the huge number of items like smart phones, tablets, laptops, etc. that we use. These items contain rare metals like gold, platinum, silver, palladium, etc, that can be recovered through recycling and reused for different purposes. They also contain toxic items like lead, mercury, nickel, etc. therefore, is it important to dispose of these items properly. Most cities have recycling centres with separate drop off points for e-waste where you can send your electronic waste for recycling.

The recycling process for e-waste involves extracting metals from electronic devices and using them in other products. This process can help reduce the need for mining precious metals and make it easier for manufacturers to meet their regulatory requirements for recycling materials like copper, aluminium and steel.

Some e-waste items can also be reused by having them refurbished for reuse instead of disposing of them. There are services for the collection of smartphones and computers for refurbishing for example. Some of these services pay you to collect such e-waste items.

Hazardous Waste

Hazardous waste items are waste that could potentially harm us or the environment. Some of the waste we generate at home and at work are hazardous in nature and could potentially cause harm. Items like batteries and cleaning chemicals are some of the hazardous waste items we generate at home.

Hazardous waste should be collected separately for treatment and disposal as hazardous waste. If you are not sure of how to dispose of any of the hazardous waste items you generate, you can call your local authority for advice. Industrial facilities generate a lot of this class of waste.

Most jurisdictions have regulatory guidelines for hazardous waste disposal that industrial producers of such waste must comply with. It typically starts with proper classification and storage in suitable containers with labelling that complies with established guidelines.

There are waste management companies specialised in hazardous waste management that can be contracted for the safe treatment and disposal of hazardous waste items. Depending on the type, some of them can be treated for reuse in other industries.

Waste Management Reports and Improvement

To track progress and gain insights on performance and improvement, it is important to collect data on the different waste streams and performance on set recycling targets. A waste management report should include set objectives and recycling targets defined for the facility in question. Data from Logs from waste collection for the different waste streams generated should be presented with comparison of percentage contribution of each waste stream.

This will help track performance against recycling targets. Based on the performance, it should include recommendations for improvement on the goals set out in the waste management plan. A sample of the table for a waste management report is included in Appendix II.

A waste management plan is a crucial first step in organising efforts at sustainable waste management into a plan that is concise, provides guidelines and procedures for managing all types of waste with measurable outcomes for achieving recycling targets. I hope this plan is useful to you; you can adapt it as needed.

With a waste management plan in place, you can easily identify and dispose of wastes to help conserve the environment. It is important that everyone plays their part by being aware of what they are throwing away and where it should go.

Appendix I: Waste Audit Template

Appendix II: Waste Management Report Template

Related Article

A Comprehensive Guide to Battling Plastic Pollution in the Ocean

Turning Trash to Power – A Comprehensive Guide to Waste-to-energy Systems

The Essential Guide to eWaste Recycling: Environment and Economy

From Waste to Landfill: Understanding How Landfills Work

Navigating Nuclear Waste Disposal: Challenges and Opportunities for a Sustainable Future

Comprehensive Guide to Mining Waste Management

Understanding the Science Behind Medical Waste Incineration

A Comprehensive Guide to Medical Waste Management: Why Hiring a Professional Company is Essential

Waste Corner is a culmination of all the experiences I have. It will feature blog articles on everything waste management and the environmental sector.

- Privacy Policy

- Waste Management Operations

- Saving The Planet

Copyright 2022 © All Right Reserved Powered By Fitch Technlogies

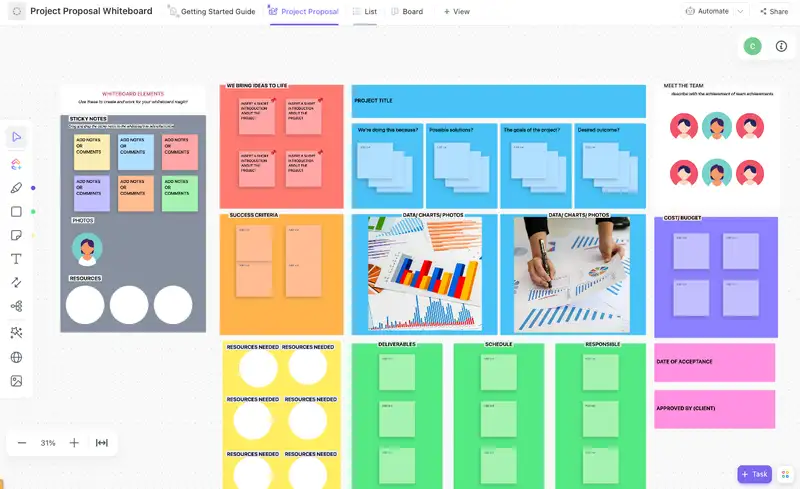

Waste Management Project Proposal Template

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

Waste management is a pressing issue that affects our environment, communities, and future generations. If you're passionate about making a positive impact and want to propose a waste management project, ClickUp's Waste Management Project Proposal Template is the perfect tool to get started.

With this template, you'll be able to:

- Clearly outline the goals, objectives, and scope of your waste management project.

- Identify and assess key stakeholders, including local authorities and community members, to ensure collaboration and support.

- Develop a comprehensive timeline, budget, and resource plan to effectively manage the project from start to finish.

- Present your proposal in a professional and compelling way, using ClickUp's intuitive features to create visually appealing documentation.

Ready to turn your waste management vision into a reality? Use ClickUp's Waste Management Project Proposal Template today and make a difference in the world!

Benefits of Waste Management Project Proposal Template

The Waste Management Project Proposal Template offers numerous benefits for organizations looking to tackle waste management effectively. Here are just a few:

- Streamlined project planning and execution, ensuring all waste management initiatives are well-organized and efficient

- Clear communication of project goals, objectives, and timelines to stakeholders and team members

- Comprehensive analysis of waste management strategies, allowing for informed decision-making and resource allocation

- Increased accountability and transparency throughout the project, ensuring all tasks and responsibilities are clearly defined and tracked

- Improved sustainability practices, leading to reduced waste generation and environmental impact.

Main Elements of Waste Management Project Proposal Template

ClickUp's Waste Management Project Proposal template is designed to help you streamline your waste management projects and proposals. Here are the main elements of this Whiteboard template:

- Custom Statuses: Track the progress of your waste management projects with two customizable statuses - Open and Complete.

- Custom Fields: Utilize custom fields to capture important information related to your waste management projects, such as project details, budget estimates, and timelines.

- Project Proposal View: Use the Project Proposal view to outline the scope, objectives, and deliverables of your waste management project. This view allows you to collaborate with your team and stakeholders to ensure everyone is aligned.

- Getting Started Guide View: The Getting Started Guide view provides a step-by-step roadmap for initiating and executing your waste management project. It helps you stay organized and ensures that all necessary tasks and actions are completed.

With ClickUp's Waste Management Project Proposal template, you can effectively plan, execute, and monitor your waste management projects from start to finish.

How to Use Project Proposal for Waste Management

If you're working on a waste management project proposal, you can follow these steps to effectively use the Waste Management Project Proposal Template in ClickUp:

1. Define the problem and goals

Start by clearly defining the waste management problem you aim to address. Identify the specific goals you want to achieve with your project, such as reducing landfill waste, implementing recycling programs, or improving waste disposal practices.

Use a Doc in ClickUp to outline the problem and goals, providing a clear and compelling explanation of why your project is necessary.

2. Develop a comprehensive plan

Next, develop a detailed plan that outlines the strategies and actions you will undertake to achieve your waste management goals. This may include implementing recycling initiatives, conducting waste audits, educating the community, or partnering with waste management companies.

Use tasks in ClickUp to break down your plan into actionable steps, assigning responsibilities and setting deadlines for each task.

3. Determine the budget and resources

Estimate the financial resources and materials needed to execute your waste management project. Consider expenses such as equipment, personnel, waste collection services, and community outreach materials. Additionally, identify any external resources or partnerships that may be required.

Create custom fields in ClickUp to track and calculate your project budget, ensuring that all costs are accounted for.

4. Craft a persuasive proposal

Now it's time to put together a compelling waste management project proposal that clearly communicates your plan, goals, and budget. Make sure to include relevant data, research, and case studies to support the effectiveness of your approach. Highlight the potential environmental and social benefits of your project.

Use the Docs feature in ClickUp to create a visually appealing proposal, incorporating images, charts, and graphs to enhance your message. You can also collaborate with team members to review and refine the proposal.

By following these steps and utilizing the Waste Management Project Proposal Template in ClickUp, you can effectively organize and present your waste management project, increasing the chances of securing support and funding for your initiative.

Get Started with ClickUp's Waste Management Project Proposal Template

Environmental organizations and waste management companies can use the Waste Management Project Proposal Template to streamline the process of proposing and implementing waste management projects.

First, hit “Get Free Solution” to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you’d like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to manage waste efficiently:

- Use the Project Proposal View to outline and present your waste management project to stakeholders

- The Getting Started Guide View will help you set clear guidelines and deadlines for each stage of the project

- Organize tasks into two different statuses: Open and Complete, to keep track of progress

- Assign team members to specific tasks and designate deadlines for each task

- Collaborate with team members and stakeholders to brainstorm ideas and create a concrete plan

- Set up notifications to stay updated on task progress and receive feedback from stakeholders

- Monitor and analyze tasks to ensure the successful completion of the waste management project.

Related Templates

- SEO Project Proposal Template

- Tutoring Program Project Proposal Template

- Tournament Project Proposal Template

- Cricket Tournament Project Proposal Template

- Solar Street Light Project Proposal Template

Template details

Free forever with 100mb storage.

Free training & 24-hours support

Serious about security & privacy

Highest levels of uptime the last 12 months

- Product Roadmap

- Affiliate & Referrals

- On-Demand Demo

- Integrations

- Consultants

- Gantt Chart

- Native Time Tracking

- Automations

- Kanban Board

- vs Airtable

- vs Basecamp

- vs MS Project

- vs Smartsheet

- Software Team Hub

- PM Software Guide

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- My Bibliography

- Collections

- Citation manager

Save citation to file

Email citation, add to collections.

- Create a new collection

- Add to an existing collection

Add to My Bibliography

Your saved search, create a file for external citation management software, your rss feed.

- Search in PubMed

- Search in NLM Catalog

- Add to Search

A methodology for solid waste characterization based on diminishing marginal returns

Affiliation.

- 1 Department of Civil Engineering, Indian Institute of Technology Kanpur, Kanpur 208016, India.

- PMID: 16600585

- DOI: 10.1016/j.wasman.2006.02.007

A methodology is developed for estimating the number of waste sorts for characterizing solid wastes into categories based on diminishing minimum incremental information. Convergence in the square of the coefficient of variation with successive waste sorts is used to indicate cost-efficient termination of sampling at substantially reduced numbers of sorts in comparison with existing methodologies. These findings indicate that the numbers of waste sorts beyond that determined using the proposed methodology do not add substantial marginal gains in information and/or reduction in the confidence interval of the estimate. The methodology is demonstrated using waste composition analyses from the Greater Vancouver Regional District where 22 waste sorts are examined. The proposed methodology is simple, and the number of waste sorts can be estimated with a hand-held calculator and utilized in the field.

PubMed Disclaimer

Similar articles

- Strategy for use of alternative waste sort sizes for characterizing solid waste composition. Sharma M, McBean E. Sharma M, et al. Waste Manag Res. 2009 Feb;27(1):38-45. doi: 10.1177/0734242X07082764. Waste Manag Res. 2009. PMID: 19220991

- Relation of waste generation and composition to socio-economic factors: a case study. Bandara NJ, Hettiaratchi JP, Wirasinghe SC, Pilapiiya S. Bandara NJ, et al. Environ Monit Assess. 2007 Dec;135(1-3):31-9. doi: 10.1007/s10661-007-9705-3. Epub 2007 Apr 21. Environ Monit Assess. 2007. PMID: 17450419

- Municipal solid waste composition determination supporting the integrated solid waste management system in the island of Crete. Gidarakos E, Havas G, Ntzamilis P. Gidarakos E, et al. Waste Manag. 2006;26(6):668-79. doi: 10.1016/j.wasman.2005.07.018. Epub 2005 Oct 3. Waste Manag. 2006. PMID: 16207528

- Methods for household waste composition studies. Dahlén L, Lagerkvist A. Dahlén L, et al. Waste Manag. 2008;28(7):1100-12. doi: 10.1016/j.wasman.2007.08.014. Epub 2007 Oct 24. Waste Manag. 2008. PMID: 17920857 Review.

- Integrated waste management--looking beyond the solid waste horizon. Seadon JK. Seadon JK. Waste Manag. 2006;26(12):1327-36. doi: 10.1016/j.wasman.2006.04.009. Epub 2006 Jun 9. Waste Manag. 2006. PMID: 16765038 Review.

- A method for determining the recycling value of unprocessed municipal solid waste in one cubic meter waste composition analysis technique. Hemali NA, De Alwis AAP, Wijesundara M, Edirisinghe LGLM. Hemali NA, et al. MethodsX. 2024 Mar 9;12:102626. doi: 10.1016/j.mex.2024.102626. eCollection 2024 Jun. MethodsX. 2024. PMID: 38559383 Free PMC article.

- Exploration and prediction of wet season municipal solid waste for power generation in Ilorin metropolis, Nigeria. Ibikunle RA. Ibikunle RA. J Mater Cycles Waste Manag. 2022;24(4):1591-1602. doi: 10.1007/s10163-022-01395-9. Epub 2022 Apr 22. J Mater Cycles Waste Manag. 2022. PMID: 35492374 Free PMC article.

- The quantity of food waste in the garbage stream of southern Ontario, Canada households. van der Werf P, Seabrook JA, Gilliland JA. van der Werf P, et al. PLoS One. 2018 Jun 13;13(6):e0198470. doi: 10.1371/journal.pone.0198470. eCollection 2018. PLoS One. 2018. PMID: 29897964 Free PMC article.

- Environmental impact assessment of municipal solid waste management options using life cycle assessment: a case study. Yadav P, Samadder SR. Yadav P, et al. Environ Sci Pollut Res Int. 2018 Jan;25(1):838-854. doi: 10.1007/s11356-017-0439-7. Epub 2017 Oct 23. Environ Sci Pollut Res Int. 2018. PMID: 29063409

Publication types

- Search in MeSH

LinkOut - more resources

Full text sources.

- Elsevier Science

- Citation Manager

NCBI Literature Resources

MeSH PMC Bookshelf Disclaimer

The PubMed wordmark and PubMed logo are registered trademarks of the U.S. Department of Health and Human Services (HHS). Unauthorized use of these marks is strictly prohibited.

Advertisement

A city of circular economy: advancement of cost-effective methods for resolving conflicts of investment in urban resilience

- Published: 06 September 2024

Cite this article

- Yasser ElSayed Fouda ORCID: orcid.org/0000-0002-3874-0966 1 &

- Deena Mohamed ElKhazendar 2

In recent years, losses associated with disasters have increased considerably. Cities are hubs of economic growth, fueling their national economies. The resilience of this growth is at risk, however, from unplanned-for shocks and ongoing stresses, facing increasing environmental, social, and economic challenges. Various literature reviews have revealed the importance of urban resilience, but most have failed to address cost-effective methods for implementing resilience in urban conflicts. Finding new innovative approaches, that are the cheapest and the easiest to implement, to overcome the challenges, are limited. Investors are struggling with a range of obstacles when it comes to investing in resilience. To help in closing the implementation gap, a comprehensive framework of sustainable approaches emphasizing the notion of circular economy is developed across a range of spatial scales throughout its phases of emergency and risk management cycle. The main aim is to enable adaptation and the development of cost-effective solutions in response to future challenges and thus encourage investments in resilient cities. A cost benefit analysis, applied to a hypothetical city, is developed for each innovative approach at different spatial levels. The proposed analysis has proven that innovative approaches are cost effective, as their net economic benefit exceeds their upfront cost. Besides that, they tend to reduce a variety of disaster losses and emphasize the notion of circular economy. In overall, the framework analysis has revealed its ability to act as a protective dome to govern, manage, and finance sustainable low-cost approaches in any new urban formation.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Flood Protection and Land Value Creation – Not all Resilience Investments Are Created Equal

Strengthening Urban Resilience/Disaster Risk Management in Asian Cities

Can we pull resilience from the rubble? experiencing earthquakes in Mexico City

Explore related subjects.

- Artificial Intelligence

Ahern, J. (2013). Urban landscape sustainability and resilience: the promise and challenges of integrating ecology with urban planning and design. Landscape Ecology, 28 (6), 1203–1212. https://doi.org/10.1007/s10980-012-9799-z

Article Google Scholar

Avila, S., Banuls, V., & Gallego, M. (2021). Is urban resilience a phenomenon on the rise? A systematic literature review for the years 2019 and 2020 using textometry. International Journal of Disaster Risk Reduction, 66 (11), 102588. https://doi.org/10.1016/j.ijdrr.2021.102588

Bush, J., & Doyon, A. (2019). Building urban resilience with nature-based solutions: How can urban planning contribute? Cities, 95 , 102483. https://doi.org/10.1016/j.cities.2019.102483

Calheiros, C. S. C., & Stefanakis, A. I. (2021). Green roofs towards circular and resilient cities. Circular Economy and Sustainability . https://doi.org/10.1007/s43615-021-00033-0

Chen, M., Lu, Y., Peng, Y., Chen, T., & Zahng, Y. (2022). Key Elements of attentions for enhancing CUrban resilience: A comparison of Singapore, Hong Kong and Hangzhou. Buildings, 12 (3), 340. https://doi.org/10.3390/buildings12030340

Chmutina, K., Lizarralde, G., Dainty, A., Bosher, L. (2016). Unpacking resilience policy discourse. Loughborough University . Journal contribution. https://hdl.handle.net/2134/21496

Cingolani, R. (2021). Smart, sustainable, and resilient cities: the power of nature-based solutions, UN environment program, a working paper for the G20 , Italia. https://wedocs.unep.org/bitstream/handle/20.500.11822/36586/SSRC.pdf?sequence=1&isAllowed=y

Data Smart City Solutions. (2022). Turning data into equity: Lessons from San-Diego . Harvard. https://datasmart.hks.harvard.edu/?utm_source=os&utm_campaign=redirect_analysis

Dhawan, P. (2020). Circular economy guidebook for cities . V8. https://circulareconomy.europa.eu/platform/sites/default/files/circular_cities_publication.pdf

Drobniak, A. (2012). The urban resilience - economic perspective . University of economics in Katowice,10. 6–20. https://www.researchgate.net/publication/330325443 _The urban resilience economic perspective.

Ellen MacArthur Foundation. (2023). Circular Cities: Thriving, Liveable and Resilient . https://ellenmacarthurfoundation.org/topics/cities/overview

European Commission. (2020). Towards an EU research and innovation policy agenda for nature-based solutions and re-naturing cities . https://www.greengrowthknowledge.org/sites/default/files/downloads/resource/Guarnacci_Nature-Based%20Solutions.pdf

Fouda, Y., & ElKhazendar, D. (2023). Achievement of resilience in urbanism: A prototype for a simulative methodology. Alexandria Engineering Journal, 70 , 145–168. https://doi.org/10.1016/j.aej.2023.02.035

GFDRR, World Bank Group. (2021). Global program on nature-based solutions for climate resilience, A catalogue of nature-based solutions for urban resilience . https://openknowledge.worldbank.org/entities/publication/c33e226c-2fbb-5e11-8c21-7b711ecbc725

Goyal, J. (2023). Passive Strategies for Building Design in Tropical Climates: A Comprehensive Guide . NOVATR. https://www.novatr.com/blog/passive-design-strategies-tropical-climate

HMIDP, J., Van Roon M., Knight-Lenihan, S. (2014). Resilience planning: An innovative approach in dealing with urban vulnerabilities and adaptation to prioritize opportunities for uncertain urban futures . School of Architecture & Planning, University of Auckland, New Zealand. https://researchspace.auckland.ac.nz/handle/2292/24725

Jabareen, Y. (2013). Planning the resilient city: Concepts and strategies for coping with climate change and environmental risk. Cities, 31 , 220–229. https://doi.org/10.1016/j.cities.2012.05.004

Kasprzyk, M., Szpakowski, W., Poznańska, E., Boogaard, F. C., Bobkowska, K., & Gajewska, M. (2022). Technical solutions and benefits of introducing rain gardens—Gdańsk case study. Science of the Total Environment, 835 , 155487. https://doi.org/10.1016/j.scitotenv.2022.155487

Article CAS Google Scholar

Kopsieker, L., Gerritsen, E., Stainforth, T., Lucic, A., Costa Domingo, G., Naumann, S., Röschel, L., Davis, M. (2021). Nature-based solutions, and their socio-economic benefits for Europe's recovery: Enhancing the uptake of nature-based solutions across EU policies . Institute for European Environmental Policy. https://www.ecologic.eu/17770

Kumar, P. (2019). Nature based solutions can help protect us from weather and climate related natural hazards, Smart Water Magazine , University of Surrey. https://smartwatermagazine.com/news/university-surrey/nature-based-solutions-can-help-protect-us-weather-and-climate-related

Li, P., Balsalobre-Lorente, D., Wang, Q., Zhang, Q., & Shah, S. A. R. (2024). Impact of sectoral mix on environmental sustainability: How is heterogeneity addressed? Gondwana Research, 128 , 86–105. https://doi.org/10.1016/j.gr.2023.09.018

Mallawarachchi, H., Silva, L., Rameezdeen, R. (2013). Green buildings, resilience ability and the challenge of disaster risk . https://www.researchgate.net/publication/277892802_Green_buildings_resilience_ability_and_the_challenge_of_disaster_risk .

Mittal, H., Yang, B. M., & Wu, Y. M. (2022). Progress on the earthquake early warning and shake maps system using low-cost sensors in Taiwan. Geoscience Letters, 9 , 42. https://doi.org/10.1186/s40562-022-00251-w

Moreau, M., Ménascé, D. (2018). Urban resilience: introducing this issue and summarizing the discussions. The journal of field actions: Field action science reports. Resilient Cities , Special Issue 18. https://journals.openedition.org/factsreports/4629

OECD. (2019). Enhancing the contribution of digitalisation to smart cities of the future, Smart cities final . https://www.oecd.org/regional/regionaldevelopment/Smart-Cities-FINAL.pdf

Resilient Cities Program. (2022). Resilience point of view series, 100 Resilient Cities: Transport . https://resilientcitiesnetwork.org/downloadable_resources/UR/Resilience-Point-of-View-Transport.pdf .

Shah, S. A. R., Zhang, Q., Balsalobre-Lorente, D., & Pilař, L. (2023). Technology, urbanization and natural gas supply matter for carbon neutrality: A new evidence of environmental sustainability under the prism of COP26. Resources Policy, 82 , 103465. https://doi.org/10.1016/j.resourpol.2023.103465

Shamsuddin, S. (2020). Resilience resistance: The challenges and implications of urban resilience implementation. Cities . https://doi.org/10.1016/j.cities.2020.102763

Snep, R., Voeten, J., Mol, G., & Van, T. (2020). Nature based solutions for urban resilience: A Distinction between no-tech, low-tech and high-tech solutions. Frontiers in Environmental Science . https://doi.org/10.3389/fenvs.2020.599060

Solomon, S., Appavoo, J., Brown, V. (2020). Addressing finance and capacity barriers for nature-based solutions implementation at city level . Urban20, Riyadh. https://www.urban20.org/wp-content/uploads/2020/11/Addressing-Finance-and-Capacity-Barriers.pdf

Spaans, M., & Waterhout, B. (2017). Building up resilience in cities worldwide—Rotterdam as participant in the 100 resilient cities programme. Cities, 61 , 109–116.

Takavakoglou, V., Pana, E., Skalkos, D. (2022). Constructed wetlands as nature-based solutions in the post-COVID agri-food supply chain: Challenges and opportunities. Sustainability , 14 , 3145. https://doi.org/10.3390/su14063145 . https://www.mdpi.com/2071-1050/14/6/3145?type=check_update&version=1

TELE2. (2022). Internet of things, The role of IoT in disaster management and emergency planning . https://tele2iot.com/article/the-role-of-iot-in-disaster-management-emergency-planning/

World Bank. (2019). City Resilience Program: Program Brief: Catalyzing Urban Resilience . https://documents1.worldbank.org/curated/en/660751548946460826/pdf/134232-WP-30-1-2019-9-35-30-ProgramBriefJancompressed.pdf

World Economic Forum. (2020). How the internet of things is building smarter cities, Cities and urbanization . https://www.weforum.org/agenda/2020/03/how-the-internet-of-things-is-building-smarter-cities-72269e8b88

World Economic Forum. (2022). Climate change: How to build climate resilience into the construction industry . https://www.weforum.org/agenda/2022/03/heres-how-to-build-climate-resilience-into-the-construction-industry/

Zohou, V., Fang, H. (2022). IoT aided building fire evacuation: Comparison, Scholarly Community Encyclopaedia . https://encyclopedia.pub/entry/history/compare_revision/45094/-1

Download references

Author information

Authors and affiliations.

Department of Architectural Engineering, College of Architectural Engineering and Digital Design, Dar Al Uloom University, P.O.Box 45142, 11512, Riyadh, Kingdom of Saudi Arabia

Yasser ElSayed Fouda

Department of Applied Art and Design, Box Hill Institute Box Hill College, Al-Ahmadi Region - Mangaf - Block 1 - Street 111 - House 25, Kuwait City, Kuwait

Deena Mohamed ElKhazendar

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Yasser ElSayed Fouda .

Ethics declarations

Conflict of interest.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper, and that there is no conflict of interest in the manuscript neither internally among authors, nor externally within other authors.

Data availability

Data sharing not applicable to this article as no datasets were generated or analysed during the current study. The authors declare that there are no available datasets acquired from any source, influencing the work reported in this paper.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Innovative approaches needed at city scale —phase 1: prevent and mitigate

1.1 appendix a1: nature based solutions for: (mountainous—mountainous (volcanoes)).

Analysis of innovative approach used for landscape features | |

|---|---|

1. Mountainous | 2. Mountainous (Volcanoes) |

: Create appropriate form of vegetation on slopes and adjoining roads Create wetlands : Act as a barrier and protect settlements from potential hazards (landslides—Earthquakes—Avalanches) Act as a giant sponge that restore and filter flood water : -Reduce soil erosion -Reduce transportation of sediments into the catchment -Regulate carbon cycle and precipitation -Recharge groundwater levels, reduce water shortage and drought -Filter and treat water from impurities -Carbon sink -Safe harbors for biodiversity and agriculture havens -Act as natural air conditioner and purifier (cool air) -Serve as recreational and health services during pandemics : : Laogan Ravine (China) Innovative approach used: Increase vegetation cover on slopes (159 ha (area)) Estimated profit (over 20 years): US $ 590/ha/year i.e., US $ 77,000 (income for local people) Date: 1991–1994 Upfront cost: 170,000$ Losses prevented: US $ 5Millions

: Sponge City—Wuhan (China) Innovative approach used: Wetlands Area: 38.5 km2 (389 separate projects—45000trees) Economic Benefit: Value of land in surrounding areas have risen from US $ 631 to US $ 1471 per m Date: 2015–2017 Upfront Cost: US $ 2139 Million (US $ 600 million cheaper than grey infrastructure) Water losses prevented: US $ 220,000/year

: Southeast Queensland Storm Water Management Case Study (2010) Major Costs: US $ 52,220/hectare Major Benefits: US $ 57,110/hectare

| : Create special types of vegetation with broad leaves Create Lava tubes (natural conduits made from by-products of volcanic process) : Act as a bio-shield from (tephra and volcanic ash) Redirect lava flow underground : Reduce wind erosion during volcanic eruption -Generate electricity (Geothermal power) -Enrich Soil -Metallic ore deposit -Boost economic benefits and reduce economic collapse : : Hellisheidi–Iceland Innovative approach used: Geothermal approach Date: Project commissioned in 2006 Project Fund: US$ 800 Million Energy Produced: 2300GWh

Economic benefit: Save 30–60% on energy sources Accounts for 7% of Iceland GDP (3000USD per person each year)

N.B: Geothermal energy require high upfront cost (drilling costs) but payoff in the short and long terms #Upfront cost: US $ 34/MWh (Power plant cost (US $ 25/MWh) + Drilling cost (US $ 9/MWh)) for 320GWh/year To cut investment costs from drilling (accounts for 60% for total investment) by more than half. “EU-Funded Researchers” has developed models enabling identification of geothermal regions with high heat conductivity potential without the need for drilling

|

1.2 Appendix A2: Nature based solutions for: (Deserts—Coasts—Forests)

Analysis of Innovative approach used for landscape features | |

|---|---|

3. Deserts | 4. Coasts |

: Afforestation Wetlands : -Act as a buffer that reduce wind speed and soil erosion -Act as a giant sponge that restore and filter flood water -Keep Soil well-watered that can reduce locusts : -Act as economic inflation reduction -Reduce risk of desertification and dust storms -Restores and decrease risks of flash flood -Reduce water shortage and droughts -Reduce locusts and grasshoppers’ swarm -Serve as recreational and health services : : Green belts across China Innovative approach used: Afforestation Date: 2021 Cost (plantation): US $ 26,470/hectare/Year Economic Benefit: US $ 40,220/hectare/Year

: Dust Storms in Australia—Queensland State Innovative approach used: Afforestation Upfront Cost: US $ 9 Million. Affected Area: 3000 km long Annual Average economic loss from sandstorms: US $ 299 Million Dust storms-_What do they really cost

| : Create/restore coral and oyster reefs and kelp, and seagrass beds. In addition to implementation of: -Mangrove Forests -Saltmarshes -Sand dunes : -Serve as a buffer for tsunamis and high coastal rise -Absorb and store excess water : -Filter and treat water -Protect shorelines from erosions -Metabolize excess nutrients -Create a productive safe harbor for biodiversity -Act as: (Food and water source, recreational and health benefits, and carbon sink) Reduce economic collapse : : Cost benefit analysis in Quelimane, Mozambique Innovative Approach Used: Mangrove forests Area of Mangroves: 22 Hectares Costs (Actual costs + Additional cost) (2016): US $ 5400/Hectare (Labor—Materials—Equipment—Taxes—Licensing—Transportation) Number of trees per hectare: 364trees

Total Economic benefit (2023): US $ 5660/Hectare/Year (Fish Production—Aquaculture—Beekeeping—Storm protection) : Mangrove in Philippines Date: 2011–2015 Philippine Government Fund: US $ 22 Million Area of Mangrove: 220Hectares (544acres) Losses prevented (storm): US $ 450 Million/Year

|

5. Forests | |

|---|---|

: -Green belts -Afforestation and reforestation : Serve as a fuel break, slowing the speed and intensity of encroaching fires : -Provide recreational and health benefits -Improve air quality and esthetic value -Expand wildlife habitat -Expand carbon sink -Discourage emissions from forest fires -Incentivize the use of renewable forest and agricultural products (mechanical thinning) in energy production -Act as economic inflation reduction : : Sonoma County, California Innovative approach used: Park restoration Date: 2021 Fund from Vegetation Management Program (wildfires fuel breaks): US $ 3.8 Million for 2,000 acres Losses prevented (wildfires): US $ 37 Millions Parks valley area: 60,000 acres Park expenditures (recreation and health): US $ 12.5 Million/year Park revenue (recreation and health): US $ 15.5 Million/year Net Profit (recreation and health): US $ 3Million/year

and |

1.3 Appendix A3: Internet of things for: (all landscape features)

Analysis of innovative approach used for landscape features | |

|---|---|

All landscape features

| |

Internet of Things IoT: -Digital Technologies (Mitigation Phase) : -Analyzing the spatial and geographical information related to a specific disaster Sensors can early analyze prone areas to: -Wildfires -Tornadoes and cloud bursts -Volcanic activities -Earthquakes : -Collect near-real-time data on things like water levels, volcanic activities, and barometric readings thus preventing economic and human losses : : US West Coast Innovative approach used: Internet of things (Stand-alone-system with a low-cost acceleration sensor) Date: 2014 Upfront cost (Earthquakes early warning): Onetime payment US $ 38 Million, US $ 16.1Million/Year US West Coast area: 261,500,000 hectares Losses prevented: Protection for business and individuals worth US $ 1 Billion

|

Appendix B: Innovative approaches needed at neighbourhood scale

Innovative approach | Economic benefit/avoided disaster costs | Cost analysis examples (Investment in innovative approaches) |

|---|---|---|

1. Land-use planning strategies:

#Provision of blue (waterways)/Green (Greenery) infrastructure #Provision of open space

| -Water supply (drought) -Water Storage (flood) -Multi-Transportation nodes (Evacuation routes) -Food source -Recreational and health services (Pandemics) -Spaces for temporary infrastructure (Shelters provisions) -Multiple functions of spaces (Avoid man-made and natural disasters losses) | : Los Angeles, California saw an increase of more than 2000 jobs from its $166 million investment in blue/green infrastructure (2012–2014) : In Philadelphia, Pennsylvania (2008) 7,000 vacant lands of 8 million square feet were greened. All houses within a quarter mile of a greened lot increased in value by 2–5% annually generating US $ 100 Million in additional annual property taxes

|

2. Transportation system and mobility: Connectivity: (20 min neighborhood) Modularity and Redundancy | -Sustainable transportation methods (cycling and walking) -Health benefits (Pandemics) -Modular redundant evacuation routes -Ease transportation routes -Optimization and inclusion of evacuation routs for all society | : The estimated cost for public transportation is US $ 165 Million a year or US $ 2 billion over the long run. This is a modest amount compared to current capital commitments for rail that reaches to US $ 19—26 billion (Victoria State Government 2017) : A study completed by Queensland Government in 2011 states that for each person who walks 20 min to work and back the economy benefits US $ 8.48

: (Moreno 2020) |

3. Storm Water Management (NBS) -Tree trenches -Permeable pavement -Vegetated swales placed along streets and parking lots -Rainwater harvesting by blue/Green infrastructure (wetlands + rivers and water channels) -Tree canopy -Green streets -Land slopes | -Water supply (drought) -Water Storage (flood) -Cooling effect -Reduce urban heat island (Extreme temperature) -Health benefits (Pandemics) -Purification of air and water (Health) | : Quabbin and Wachusett nature-based solutions (22,000 acres of watershed) project for water management Fund: $130 million (for the past 20 years) Economic benefits: A water filtration plant would have cost $250 million and $4 million annually to operate and maintain

: King County public health building and Lakewood Park—Seattle (2010) Area: 65 Acres (26Hectare) Project details: (Wetlands—green streets—tree canopy—swales) Construction Cost: US $5.4 million Annual Maintenance Cost: US $153,000 One-time benefits: US $219,700 Net present Value (50 years): US $20Million Payback period: 8.7 Years

|

4. Sustainable Food Management (NBS) -Orchards (Vegetables and fruits source) -Floating greenhouse -Blue infrastructure (Fish source) | -Food Source (During disasters) -Health Benefits (Pandemics) -Stabilize the soil and prevents (soil erosions) | : In Niger (2020), orchards generate $280 million per year in ecosystem benefits and yield increase, which provide food for 2.5 million people The total additional value for provision and restoration of orchards is US $ 1140 per hectare

|

5. Renewable Energy Sources -Renewable energy sources -Biofuels and biomaterials | -Sustainable energy sources (provide power during emergencies) -Efficient energy source | : Between 2003—2012 weather related outages have cost the US of an annual average of US $ 28–53 billion : Smart renewable sources smart grids in Washington, DC, and Pennsylvania (68.34 square miles) (2012) reduced weather Sandy storm’s impact for power outages Fund from The American Recovery and Reinvestment act of 2009: US $ 4.5 billion

The US department of energy states that the benefit cost ratio for wind power is 18 to 1

|

Appendix C: Innovative approaches needed at building scale

Innovative approach | Economic benefit-avoided disaster costs | Cost analysis examples (investments in innovative approaches) |

|---|---|---|

1. Landscape and water management -Rain Gardens (Shallow vegetated basins that collects and absorbs runoff from rooftops, sidewalks, and streets) -Permeable pavements (Pervious concrete, porous asphalt, and interlocking pavers) -Terraces and slopes -Bioswales (Collect polluted stormwater runoff and filter out pollution) | -Reduce and treat stormwater runoff (Flood and drought) -Air and water purifier (Pandemics) -Water storage (Drought and Flood) -Cool temperature (Extreme temperature) -Food supply | : The Camden County Utility Authority (2018) Area of county: 8723 square miles (7354 square miles are land) Cost upfront: $5.4 million loan from the New Jersey Infrastructure Bank to construct rain gardens and porous concrete sidewalks Cost Savings: $3.1 million over the 30-year loan

: Rain Garden cost = (US $ 240 + US $ 40.09/Square ft)—(Maintenance = US $ 4/ Square ft) Permeable pavements = (US $ 6/ Square ft)—(Maintenance 0.02/ Square ft) Ex: 21 Custer St. Jamaica Plain (2022—2025) Lot Size: 644 Square meter Upfront cost: US $ 363,782 (Includes: bioswale—rain gardens—permeable pavements)

|

2. Building Exterior Management -Materials selection (Bio-Based Materials) -Phase change materials—PCMs (Absorb heat during the day and releases it during the night) -Cost effective waterproof timber (Oak and Cedar) construction -Green building façade -Green roofs | -PCMs materials can regulate temperature (Extreme temperature) -Sustainable materials selection (earthquakes) -Cool temperature (Extreme temperature) -Health Benefits (pandemics) -Air purifier (pandemics) | : Seattle Buildings (2022), Washington Seattle Buildings have PCMs encapsulated in its wall and ceiling panels Economic Benefits: Cooling costs will be as much as 98% lower than one would expect for a 77,000-square-foot building

: Green roofs cost = (US $ 500 + US $ 15/Square ft)—(Maintenance = US $ 0.75/Square ft) Green walls = US $ 1,400 Ex: 21 Custer St. Jamaica Plain (2022—2025) Lot Size: 644 Square meter Upfront cost: US $ 227,552 urban resilience, 2018

|

3. Heat Island Reduction -Green cool roofs (designed to reflect more sunlight) -Reflective pavements -Bioretention areas -Urban trees | -Cool temperature (Extreme temperature) -Reduce climate change (Global warming) | : Glasgow, Scotland Glasgow has increased its green areas by 20%, consequently, the city can cut its urban heat island effect in half by 2050

: Washington. D.C cool roofs (2018) Area: 68.34 square mile Upfront Costs: US $838 Million (Including: First cost, operations and maintenance, additional replacement, employment training) Cost Benefits: US $2.648 Billion (Including: Energy, health, financial incentives, climate change, storm water, employment benefits) Net present Value: US $ 1.8 Billion urban resilience, 2018 |

5. On Site renewable energy and energy efficiency -Building orientation (Sun and wind) -On site Renewable energy sources | -On site renewable energy sources (economic crisis) | : In 2017, University of Sussex has installed 3000 solar panels on the roof at their campus which generates 5% of their total energy use each year Upfront Cost: US $ 1.87 Million, using efficient and cheap modern panels Cost benefit: Provides (777,000 Kilowatt hours) and reduces the ongoing expenses and maintenance costs on the long run

: Solar panels cost around US $ (4 to 10 per square feet)

|

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Fouda, Y.E., ElKhazendar, D.M. A city of circular economy: advancement of cost-effective methods for resolving conflicts of investment in urban resilience. Environ Dev Sustain (2024). https://doi.org/10.1007/s10668-024-05289-8

Download citation

Received : 21 August 2023

Accepted : 27 July 2024

Published : 06 September 2024

DOI : https://doi.org/10.1007/s10668-024-05289-8

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Resilient city

- Disaster risk management

- Innovative planning approaches

- Cost–benefit remedy

- Urban conflicts

- Find a journal

- Publish with us

- Track your research

Solid waste management for sustainable development

A study of solid waste management for sound environmental development in hambantota municipal council (hmc) in sri lanka..

Methodology

When doing a social research, it is important to thoroughly describe which method is used in order to make it accessible for the readers and to be able to process it in scientific manner (Teorell & Svensson, 2007, p.54). The Research method is a supporting subject which is used to accomplish in a variety of research paradigm in many academic disciplines (Kumar, 2010, p.18). It is a system of models, procedures and techniques used to find the result of a research problem (Panneerselvam, 2004, p.2). According to Henn et al (2006, p.21), the research method encourages the researcher to investigate a particular research area from a variety of different types of data, analyze these data using different techniques and interpreting the results from a variety of different positions. However, Choices about the method are a matter of rummaging in the tool bag for the best equipment for the task in hand (Roger, 2009, p.32). Finding these best tools was necessary to carry out the research in order to precede the study successfully.

A methodology for any research study is designed in a very cautions manner and by careful examination of the related literature (Khan, 2011, p.70). Hence, the researcher could identify many different factors related to research objectives and questions of the study with the reviewed literature in the previous chapter. Based on those readings the researcher developed the methodology which include finding the research problem, creating research questions, formatting the theoretical framework in a pre-empirical stage; while designing method, data collection, data analyzing and data interpretation in the Empirical stage (see figure 5).

Source: Author Edited by using Punch (1998, p.42)

Mixed Method Strategy

The first step of developing the methodology was to decide the research strategy. According to World Health Organization (WHO, 2001, p.9), the selection of a research strategy is the core of a research method and is probably the most important decision the researcher has to make. Research strategy is the general orientation to the conduct of social research (Bryman, 2012, p.34). Many researchers focus on using a qualitative research strategy or quantitative research strategy for their studies. Nevertheless, in some situations, a second research method can be added to the study to provide an enhanced understanding of some phase of the research and enhance a primary method so that the research objectives can be best address in the study (Creswell & Clark, 2011, p. 10).

As this study focus on how Solid Waste Management (SWM) practices impact on sound environmental development, the researcher decided to use a mixed method strategy. Mixed method strategy integrates quantitative and qualitative research in a single project (Bryman, 2012, p.628). The mixed method approach collects and analyzes data, integrates the findings and draws inferences by using both qualitative and quantitative approaches in a single study (Taskkori & Creswell, 2007, p.4). However, the research largely relied on the qualitative approach which is sequentially followed by a quantitative approach within the entire research process. The decision towards a mixed method developed because the two methods together result in a better understanding of the problem of the study (Heise-Biber & Leavy, 2008, 365). Especially, the Research Questions were suited for mixed methods as one data source was insufficient to answer all questions. According to Creswell & Clark (2011, p. 8), one type of evidence may not tell the complete story, or the researcher may lack confidence in the ability to address the problem. Therefore, using mixed methods provided an opportunity to conduct the research with confidence.

At the outset of selecting the approach, the researcher needed to know advantages of mixed methods. These advantages can be used to convince readers about the value of mixed methods (Creswell & Clark, 2011, p. 12). The mixed method provided strengths that equalize the weaknesses of both qualitative and quantitative approaches. It provided more relevant data to answer the research problem than using either qualitative or quantitative approaches alone. Moreover, a mixed method approach is likely to increase the acceptance of findings and conclusions. Yet, some disadvantages were identified with this method. When data collection methods are duplicative, the costs for gathering information were essentially doubled. Same time as pointed out by Roberts (2000), it was problematic with the possible statistical measurement limitations of qualitative data when it has been quantitized as the result is moving in the same line.

Case Study Design

“Research design essentially refers to the plan or strategy of shaping the research” (Henn et al, 2006, p.46). It is a procedure plan that is adopted by the researcher “to answer questions validly, objectively, accurately and economically” (Kumar, 2011, p. 94). A research design is a statement of the object of the inquiry and the strategies for collecting the evidences, analyzing the findings and reporting those (Singh & Nath, 2007, p.154). As pointed out by Khan, (2011, p. 69), selection and formulation of a proper research scheme is very important and essential for the successful accomplishment of a research.

This study was conducted under case study design. As Stake (1995) cited in Bryman (2012, p.66), a case study research is concerned with the complexity and the particular nature of the case in the research question. The design involves detailed and intensive analysis of the case (Bryman, 2008). It is related to the criteria that are employed when evaluating social research and build a frame work for the generation of evidence that is suited both to a certain set of criteria and to the research question in which the investigator is interested (Bryman, 2012, p.45). In this Study, the benefit of conducting a case study was that it enabled an examination of the impact of SWM on Sound Environmental Development in Hambantota Urban Council (HUC). The case study investigated the practice of SWM, perspectives of local population about SWM and impact of SWM for sound environmental development. However, SWM practices are highly contextual. Therefore, this case study will not necessarily find the same findings as a similar case study in another social setting. As Bryman (2012) stated, the purpose of the case study is not to make generalizations, but rather to generate theoretical assumptions on the basis of the findings of that particular case.

3.1. Research design .

3.2. Data Collection Methods

3.3. Sampling Method .

3.4. Data analysis

3.5. Ethical consideration.

References:

Boyatzis, R.E. (1998). Transforming quantitative information: thematic analysis and code development. SAGE publication.

Bryman (2008) Social Research Methods (3rd ed.), New York: Oxford university Press.

Bryman, A. (2012). Social Research Methods, 4th edition. New York: Oxford University Press.

Cargan, L. (2007). Doing social research. Rowman & Littlefield publication.

Creswell, J.W., (2011). Designing and conduction mixed method research. SAGE publication.

Daly, Kellehear, & Gliksman (1997). The public health researcher: A methodological approach. Melbourne, Australia: Oxford University Press. pp. 611–618.

Devi, L. (1998) Areas and tools of social research. Anmol publication.

Henn, M. Weinstein, M & Forard , N. (2006) A short introduction to social research. New Delhi: Vistaar publication

Kemper, A. E; Stringfield , S. & Teddlie , C.(2003) mixed methods sampling strategy in social science research in Tashakkori, A. & Teddlie,C.(ed) Handbook of mixed method in social and behavioral research. London: Saga publication

Klenke, K (2008). Qualitative research in the study of leadership. Emerald group publication: Bingle publication Kumar, R. (2010) Research Methodology: A Step by Step Guide for Beginners, 3rd Ed. London: Sage Publications Ltd

Kumar, R., (2011). Research methodology: A step by step guide for beginner. Sage publication.

Neuman, L.W. (2007). Social research method: qualitative and quantitative methods. 6th Ed .Pearson education

Onwuegbuzie, J.A. & Tebblis, C. (2003) ‘A frame for analyzing data in mixed method research. In, Tashakkori, A. & Teddlie, C. (Ed) Handbook of mixed method in social and behavioral research. Saga publication.

Punch, F.K. (1998) introduction to social research: qualitative and quantitative approaches. Saga publication

Roberts, C.W. 2000 A Conceptual Frameworks for Quantitative Text Analysis. Quality and Quantity. http://www.public.iastate.edu/~carlos/papers/q&q2000.pdf Accessed on 2013/ 11/ 24.

Sing, Y.K & Nath, R., (2007). Research Methodology. APH Publication

Vartanian, T.P. (2010). Secondary Data Analysis. Oxford University Press

WHO (2001). Health research methodology: a guide for training in research methods. WHO publication.

Leave a comment Cancel reply

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

Proposed methodology for the definition and selection of waste management alternatives.

Contexts in source publication

Similar publications.

- Recruit researchers

- Join for free

- Login Email Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google Welcome back! Please log in. Email · Hint Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google No account? Sign up

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 07 September 2024

Application and mechanistic insights of a washing/microwave/ultrasonic ternary pretreatment for enhancing barite flotation in waste drilling fluids

- Yu Xia 1 , 2 , 3 , 4 ,

- Hui Mao 4 ,

- Shanfa Tang 1 , 2 , 3 ,

- Shuixiang Xie 4 ,

- Hongbo Liu 5 ,

- Wen Ren 4 &

- Mingdong Zhang 4

Scientific Reports volume 14 , Article number: 20887 ( 2024 ) Cite this article

Metrics details

- Chemical engineering

- Environmental chemistry

- Green chemistry

- Process chemistry

- Surface chemistry

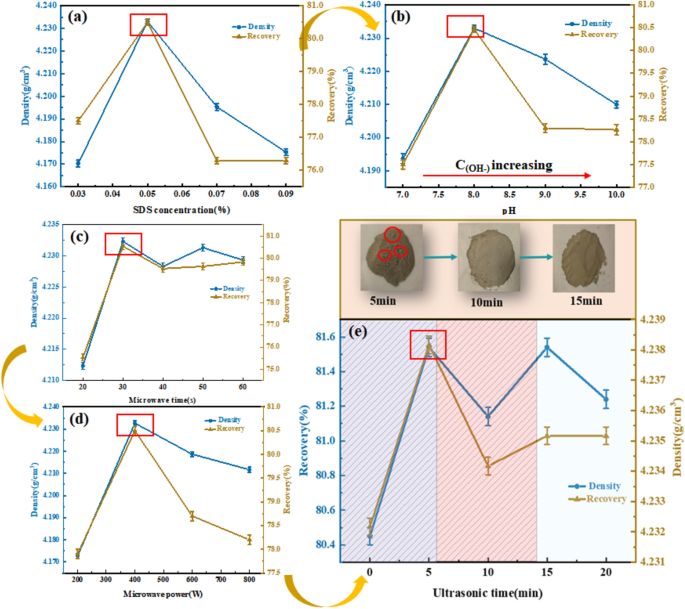

A quantity of recoverable barite exists in high-density waste drilling fluid. Based on the inefficiencies and complexities of existing recycling methods, a novel pre-treatment approach which includes clean-breaking, high-speed washing, ultrasonic dispersion, and microwave heating and a new depressant (Gellan Gum) was proposed. The floatability, separation efficiency and mechanism were discussed by SEM, adsorption capacity, zeta potential measurements and contact angle tests. The results of reverse flotation experiments results indicated that secondary water washing proves highly effective in enriching a significant quantity of barite solid phase. Subsequent microwave-ultrasonic and flotation can obtain barite of high quality with recovery and density reaching 81.5% and 4.238 g/cm 3 , respectively. It can be utilized directly in the preparation of drilling fluid. Mechanism studies shown that the per-treatments substantially enhances the barite grade while effectively eliminating low-density solid phases adhering to the barite surface, thus exposing additional contact points between the constituents so as to improve flotation separation. This new recovery scheme has environmental advantages and great reference value for the separation of barite within high-density waste drilling fluids.

Introduction

As a pivotal global strategic mineral resource, barite finds extensive applications in petrochemical, medical protection, textiles, and construction materials owing to its specific gravity, non-toxic nature, non-magnetic properties, and ability to absorb various types of radiation 1 , 2 . In ultra-deep drilling, 85 ~ 90% of barite is frequently used as a weighting agent in drilling mud, particularly in the booming 10,000 m ultra-deep drilling sector. There is a substantial demand for barite in ultra-deep drilling wells, accompanied by a significant quantity of high-density waste drilling fluids returned to drainage 3 , 4 . According to statistics, only a single well, the annual production of high-density waste drilling fluid can be up to 1 million tons, which contains a large number of barite solid phase to provide sufficient aggravating agent resources, the recovery of barite in high density waste drilling fluids not only can alleviate the tension of barite resources, but also to respond to today's global decarbonization, and build green water and green mountains of the concept of environmental protection 5 , 6 .

The structure of domestic high-density waste drilling fluid barite reuse equipment has evolved gradually from simplicity to integrated and intelligent systems. The first-generation barite reuse system primarily includes a cyclone. High-density waste drilling fluid enters the cyclone inlet under pressure and speed, where the material separates along the cyclone wall due to differences in density and particle size, moving axially downward and radially outward, achieving separation of mixtures with different densities. However, this system's simplicity limits its ability to process complex components of drilling fluid barite effectively 7 . The second generation introduced a multi-stage reuse system that integrates two centrifuges in series through an organic linkage system, dividing the process into multiple stages to handle drilling fluids. The rotational speed of the centrifuge is controlled to enhance barite recovery 8 , 9 . Currently in China, the predominant process combines cyclone separation, vibration desanding, multiple centrifuges, and solid–liquid separation. This process, although effective with a recovery rate of ≥ 80% and a processing capacity of about 2 m 3 /h, typically results in recovered barite containing approximately 15% low-density solid phase inclusions 10 , 11 , 12 . Recovering barite with particle sizes less than 74 μm and fine low-density solid phase particles is challenging with low processing capacity. Often, density adjustment of recovered barite and blending with commercially available barite are necessary, leading to economic losses and procedural complexities, failing to fully meet operational requirements. Foreign high-density waste drilling fluid treatment equipment is characterized by a more complex structure and higher integration level compared to domestic equipment. Typically employing a combination of chemical and physical treatment methods, it includes dosing tanks for adding surfactants and flocculants to pretreat mud, facilitating easier subsequent mud treatment processes 13 . The primary distinction between foreign and domestic recycling processes lies in the foreign method's utilization of chemical pretreatment and barite flotation within the combined process, significantly enhancing barite grade and density. The effectiveness of this technology in recovering barite hinges on the pretreatment process's quality and the selectivity of flotation chemicals, with varying recovery outcomes for different drilling fluid components. Thus, maintaining stable pretreatment processes and ensuring robust selectivity of flotation chemicals are critical aspects of this technology 14 , 15 .

Wang 16 et al. innovatively employed gellan gum (GG) as a selective inhibitor and incorporated sodium oleate (NaOl) to achieve concentrates. This groundbreaking approach resulted in an impressive recovery rate of 85.24% and a remarkable CaF 2 grade of 86.73% at a pH of 7.5. Guo J 17 et al. conducted a barite pure mineral flotation test, probing into the impact of sodium oleate on barite floatability under microwave radiation. The results revealed that microwave heating enhances the positive electric properties of the barite surface, consequently augmenting its specific surface area. This phenomenon, in turn, elevates the adsorption rate of sodium oleate on the barite surface, ultimately amplifying the efficiency of flotation recovery. Lev O 18 et al. used ultrasonic treatment followed by flotation for the selective separation of KCl and NaCl in saturated salt solution. Under the experimental conditions of ultrasonic treatment power of 10–75 W and resonance frequency of 20 kHz, the recovery of NaCl from potassium concentrate was reduced from 17.9 to 9.9%, and the recovery of KCl was increased from 89.9 to 95.9%, which realized the selective separation of different substances.