- • Collaborated with 5 project engineers to develop processes, test procedures and implement systems to reduce production incident rate by 200%

- • Analyzed process and product audits to improve efficiency by 90%

- • Implemented working system to ensure conformity and accuracy in production process which reduced time by 50%

- • Improved supplier quality performance from 57% in 2015 to over 80% in 2016

- • Used Appium to design and implement automated tests which reduced testing time by 30%

- • Developed inspection methods to analyze product quality which increased quality measures by 70%

- • Collaborated with 8 engineers to make recommendations for change which improve product quality by 80%

- • Worked across 9 major products to ensure products adhered to company and industry quality standards

- • Managed 10 direct reports and 120 indirect reports

- • Communicated with technicians to develop user needs for designing and 3D printing new lab devices

- • Organized and documented inspections results then presented to 3 senior management team

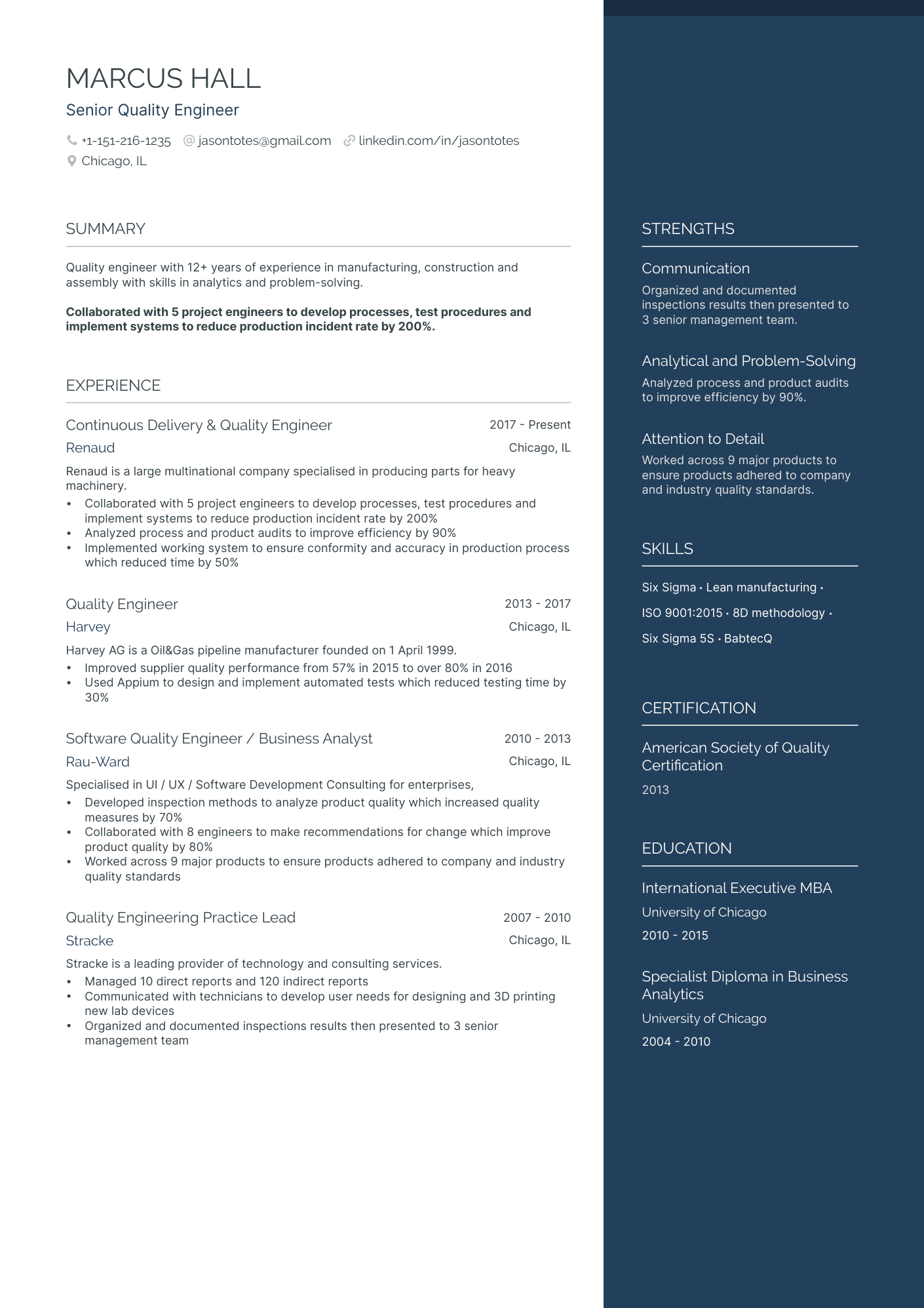

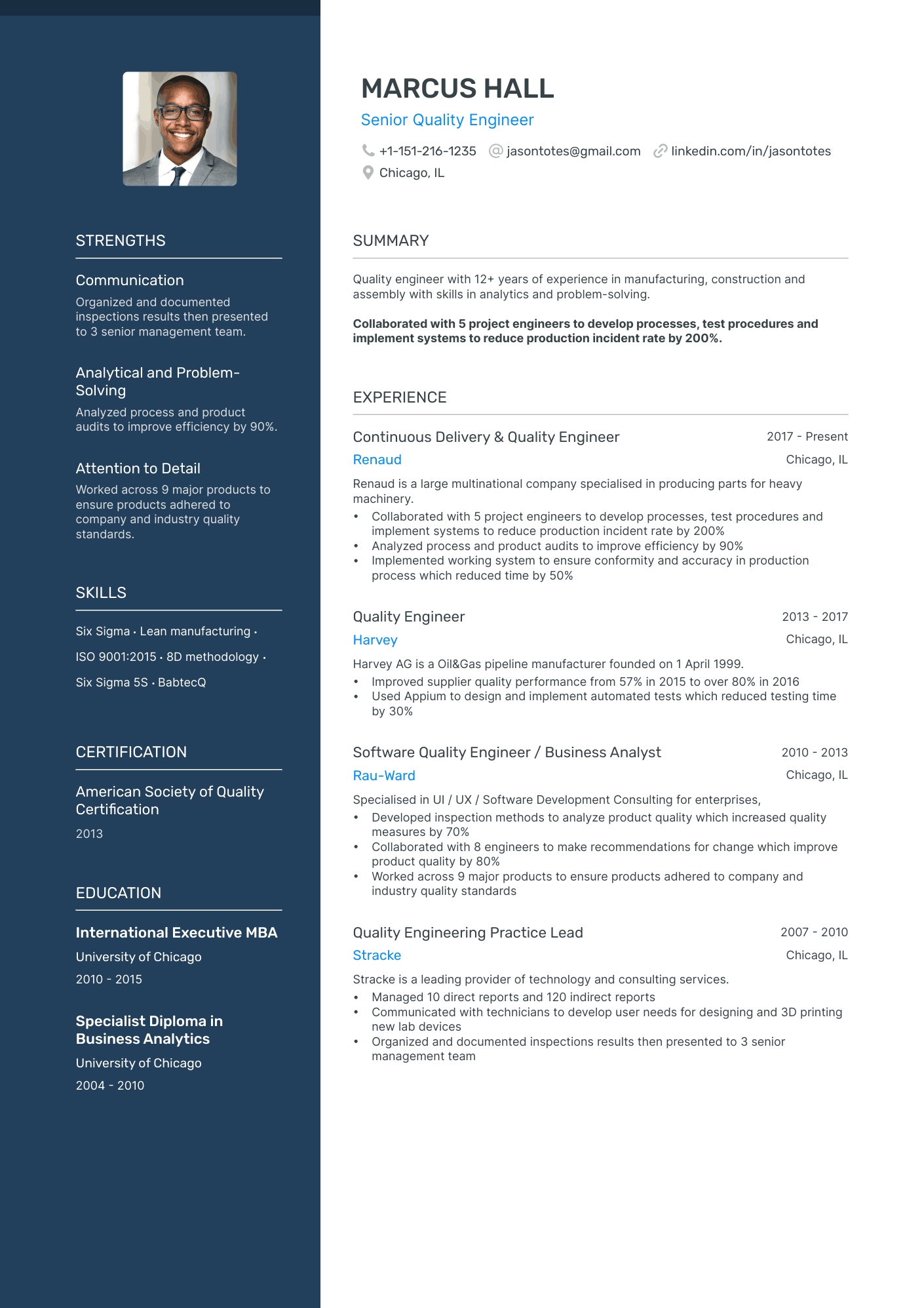

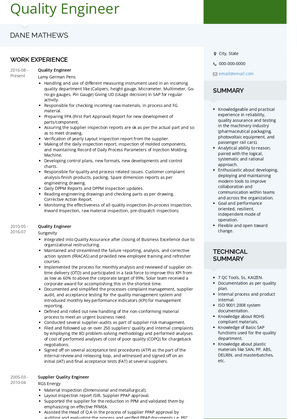

5 Quality Engineer Resume Examples & Guide for 2024

Quality Engineers ensure that products meet specified standards and customer expectations throughout the development process. Highlight your experience with quality assurance methodologies, your familiarity with regulatory requirements, and any successful projects that demonstrate your impact. Include competencies in data analysis, problem-solving, and proficiency with quality management tools. Mention your ability to enhance product reliability and your commitment to continuous improvement, which can significantly benefit potential employers.

All resume examples in this guide

Traditional

Resume Guide

Here’s what you’ll read in our quality engineer resume guide, looking for related engineering resumes let’s help you out, writing a comprehensive quality engineer resume - what you need to know, how to make an eye-catching quality engg resume header, what your quality engineer resume summary should include, how should you frame your quality engineer experience on the resume, how to describe your entry-level quality engineer experience on the resume, what skills should you include in your quality engineer resume, what’s the best way to frame education on your resume, what are the top quality engineer certificates for your resume, so, what makes a great quality engineering resume.

Before you get to evaluate projects yourself, it’s you who will fall under the scrutiny of your employer.

Employers will judge your Quality Engineer resume for your inherent problem-solving abilities, discipline, and a talent for communicating with others.

- Are you an expert in ISO 9001:2015 and Six Sigma quality management?

- Do you have the perfectionist’s attention to detail that can drive everybody insane, but guarantees the reliability of your products?

- Can you rig a test in 15 minutes to illustrate the problem to your higher management?

- Are you a positive person eager to help others and improve the process?

A quartet of yeses indicates you have the right skills and mindset. But, how do you get this across to your employer?

Tag along! In this guide, we’ll teach you how to craft an effective Quality Engineer resume that can easily double the interviews you get invited to.

- Analyze and use 10+ quality engineering resumes without repeating the same mistakes

- Learn what recruiters are looking for when reviewing Quality Engineer resumes

- How to use targeted language and specific keywords from the job description in your resume

- What role does each resume section have - header, summary, experience - and what common errors you want to avoid

- How a skills section reinforces your resume and why it helps you get past HR automation

- Where to position your engineering education and what certificates will enhance your application

- Design Engineer resume examples

- Test Engineer resume examples

- System Engineer resume examples

- Quality Control resume examples

- Project Engineer resume examples

Start with a blank sheet.

A good resume is just one page long anyway.

Begin by analyzing the criteria in the job description .

Your resume will become instantly more relevant to the recruiter if you mimic the language or your employer.

- Which industry do they operate in? What terminology is commonly used in their field?

- What keywords are most frequently used on the page? Skills, technologies, quality control methodologies?

- Which responsibilities are listed first, or emphasized in any noticeable way?

Make this the core of your quality engineering resume, and at the very least, you should pass through the automated applicant tracking system.

Even if your resume has reached a recruiter’s desk and it’s relevant to the job offer, it doesn’t mean they’ll give it more than 6 seconds of their time.

Your application can get rejected for any objective or subjective reason:

- Resume is too long...or too short

- The sections are incorrectly formatted

- The font used is too small or hard to read

- Your professional summary is not detailed or specific enough

- The work experience is too generic

As a quality engineer, you should be able to recognize inefficiency and disorganization. Act accordingly - eliminate all unnecessary details and focus on the skills and experiences which are sought after by employers.

Below are some of the major points you want to mention in your quality engineering resume.

Here's what to accent on in your Quality Engineering resume

- Extended experience in the industry of your employer - manufacturing, oil & gas, pharmacology, software development, etc.

- Mastery of quality control standards such as ISO 9001:2015

- Practical use of strategies like Total Quality Control, Six Sigma, Lean manufacturing, Lean Six Sigma and others

- Great math, statistics and data analysis skills

- Quality management software - MasterControl, CAQ.net, IntraStage, ComplianceQuest, etc.

- Strong interpersonal skills and excellent communication skills - written and verbal

- Ability to work in a team and cooperate with other departments

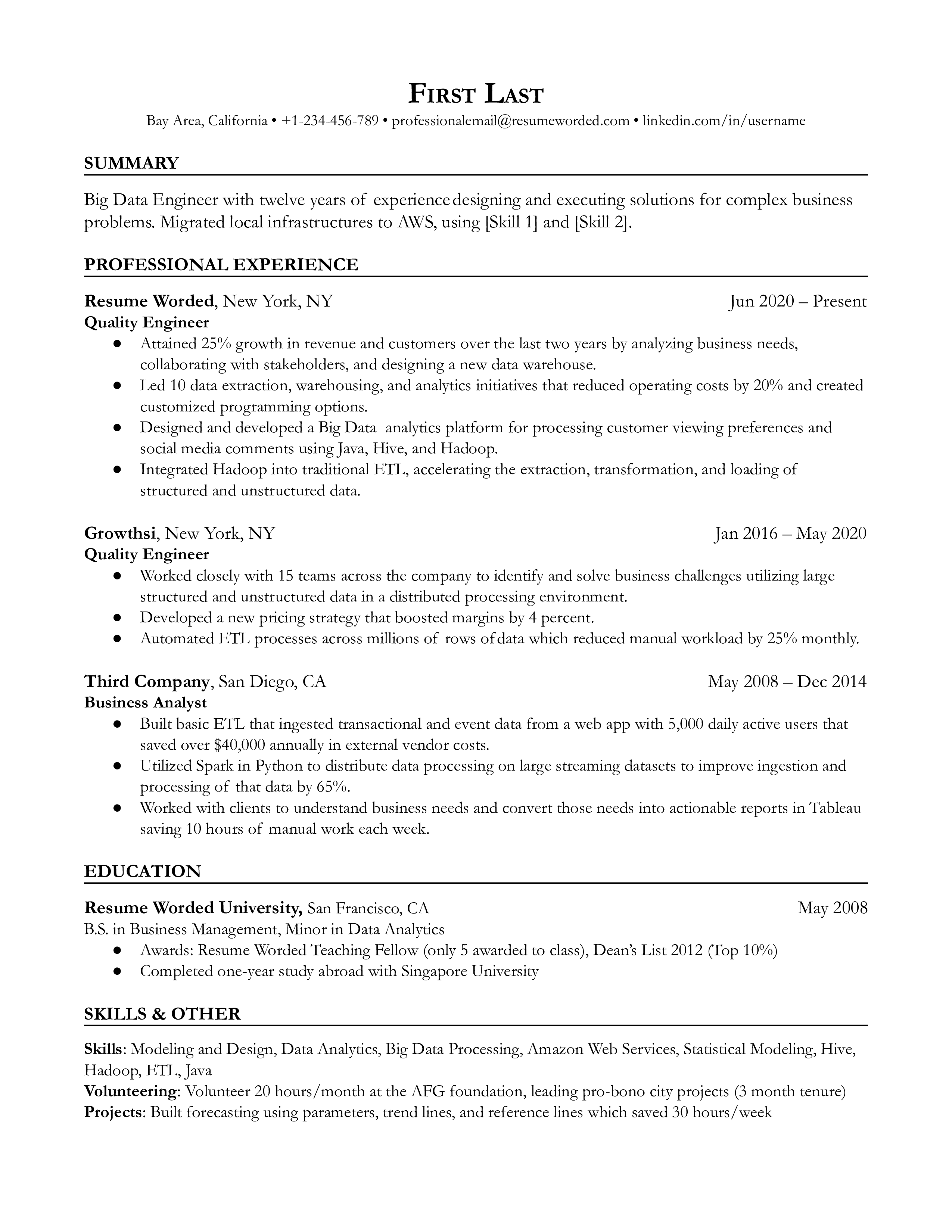

Content is important, but if you make your evaluator work hard for it, they can easily discard your resume without reading a word.

You need a proper resume format. Break down your information into sections and give them enough white space , so your resume is readable and easy to scan.

A proper quality engineering resume will include the following resume sections .

Don't forget these important quality engineer resume sections

- Resume header with your name, title and contact information

- Career summary where you pitch your proposition - experience, skills, achievements.

- Work experience section - reinforce your pitch with facts and results from your previous employment

- Skills section - invaluable in modern day resumes due to automated scanning

- Education and certification section - engineers need diplomas and specific training depending on the industry

The sections above are absolutely mandatory if you don’t want your application trashed.

Depending on your case, you may want to include additional sections to your Quality Engineer resume:

- Seniors may hold a number of achievements which will go nicely into a dedicated achievements section;

- Juniors and students who lack a lot of real-world experience will benefit from a section dedicated to their personal and school projects .

Keep in mind that your quality engineering resume needs to fit into only one page .

If any section seems irrelevant or out of place, it’s best to remove it.

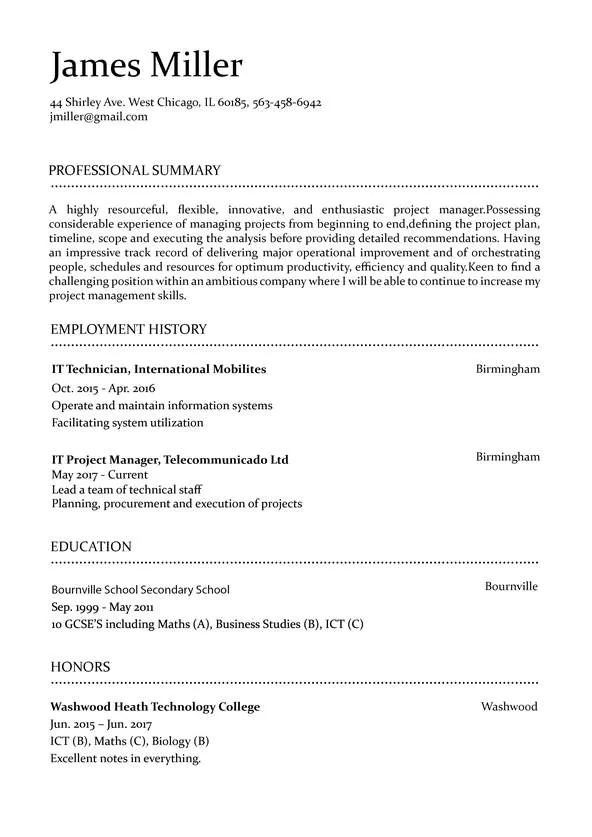

Choosing the best layout for a quality engineer resume

An optimized resume layout will help you fit the most information while remaining readable and scannable.

The chronological layout is the standard format accepted widely at every organization. List all work experience, projects, education and other notable information starting with the most recent items. If you’re part of several projects and have diverse interests and experiences, the hybrid, double-column, resume design is more favorable .

You can organize the information more efficiently putting all relevant items at the top of the page.

Whichever layout you choose, your quality engineering resume should always start with a header and summary section.

The resume header may seem like an obvious thing. You can’t get it wrong…right?

It’s deceptively simple, but as a quality engineer, you know little things often have significant impact on the whole system.

Forgetting to include some of your contact details , like location , may leave a bad impression.

Outside of worst case scenarios, there are nuances which recruiters will notice and use to distinguish candidates.

For example: How relevant your professional title is to the job title offered?

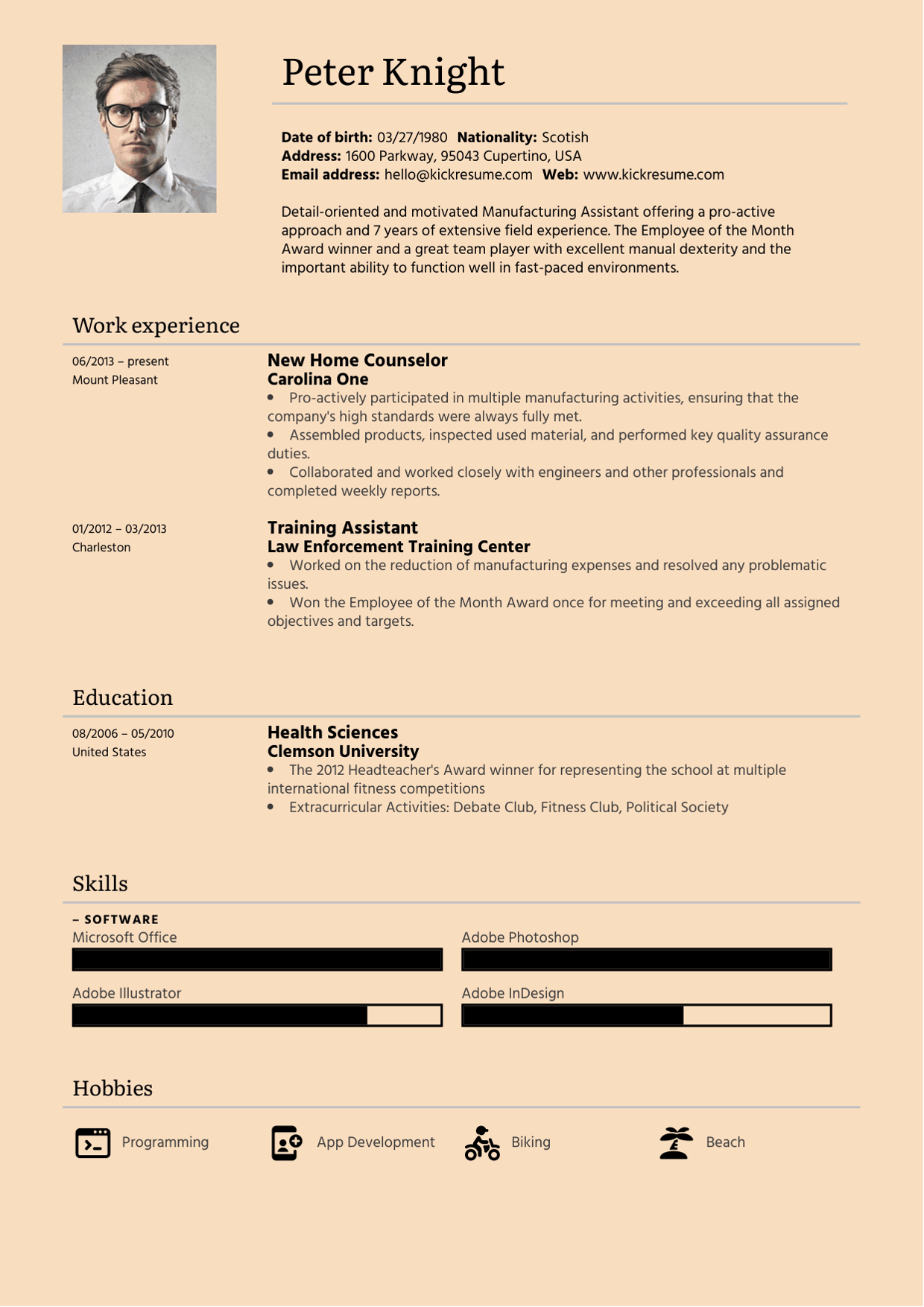

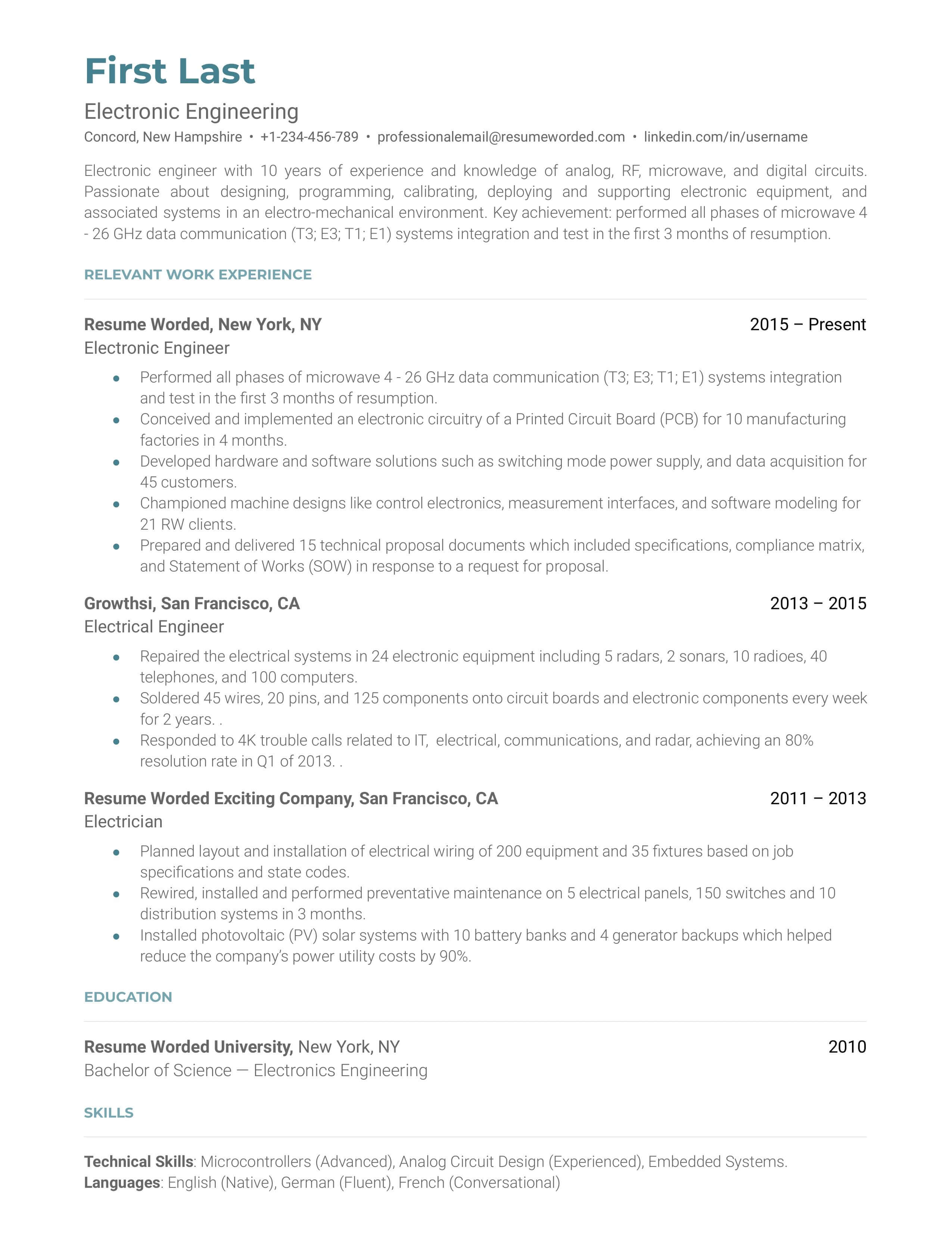

Let’s review a few quality engineer resume examples and compare.

Quality engineer resume header samples

This applicant is using an incomplete title which will easily confuse your recruiter.

The Navy is a huge organization with more than 600,000 employees.

They can be an active diver, an accountant or a quality engineer at a navy manufacturing facility.

Recruiters won’t know if you don’t put it on your resume. It may be included somewhere else on the resume, but you can’t assume they will ever get to read it.

Don’t take chances! Make sure your professional title is as close as possible to the job offer you’re applying to.

Let’s see a better quality engineering resume example.

Now this is a proper professional title. There is absolutely no mistake what Mr. Morley does for a living.

Just this detail will make a difference to a recruiter who may have 50 resumes to review and needs to shed off the dead weight quickly.

This Quality Engineer has also added their Linkedin profile , which holds additional details about them and costs nothing to add.

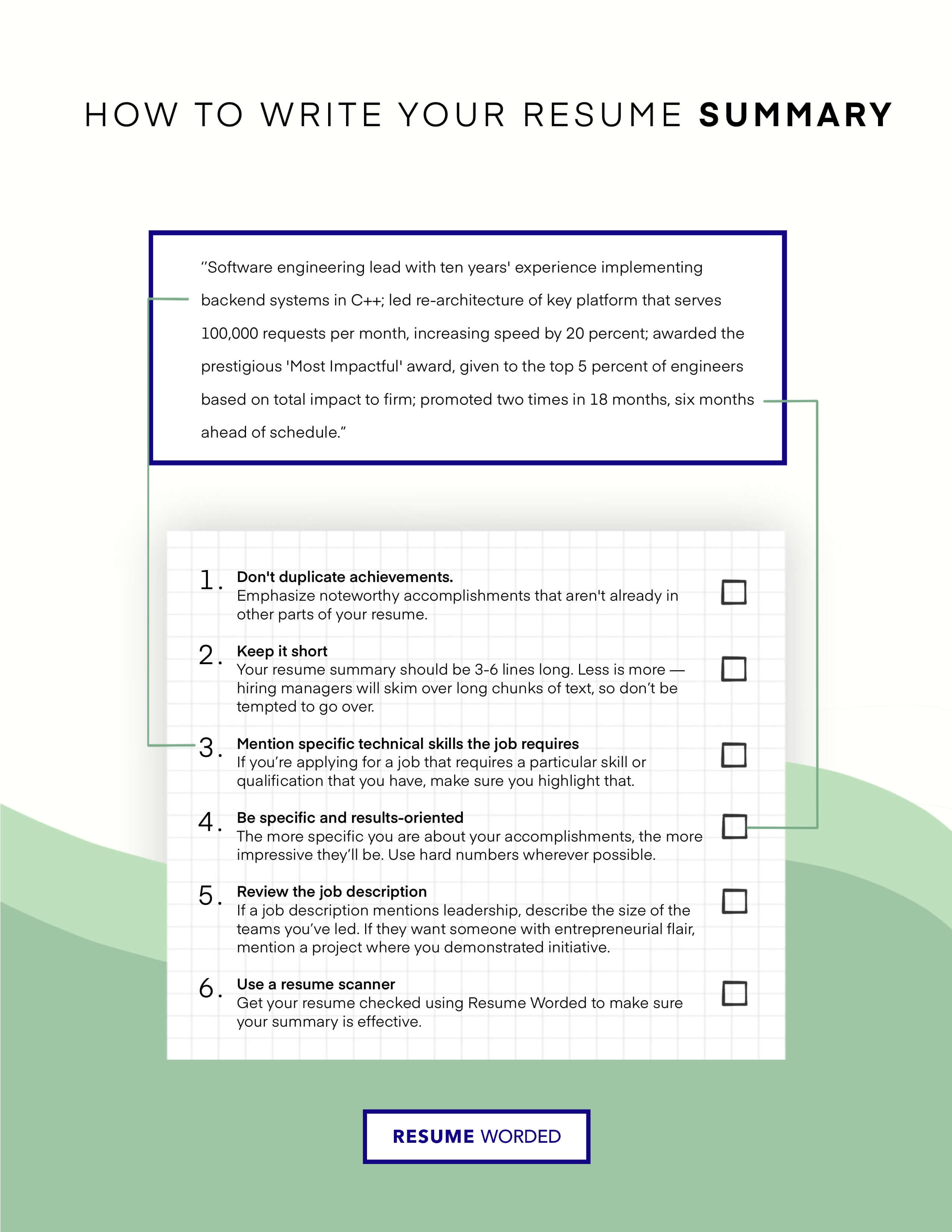

The whole purpose of the summary section is to help recruiters decide if they want to look into your application further or move on.

A decent starting point is answering the questions below:

- How much quality engineering experience you have?

- Which industries have you worked in?

- Do you have professional certifications or education qualifying you for this position?

- What technologies and methods of quality control have you exercised in your previous positions?

- Anything truly notable about yourself?

Try to wrap this information in a couple of sentences and make it as relevant as possible to the job description.

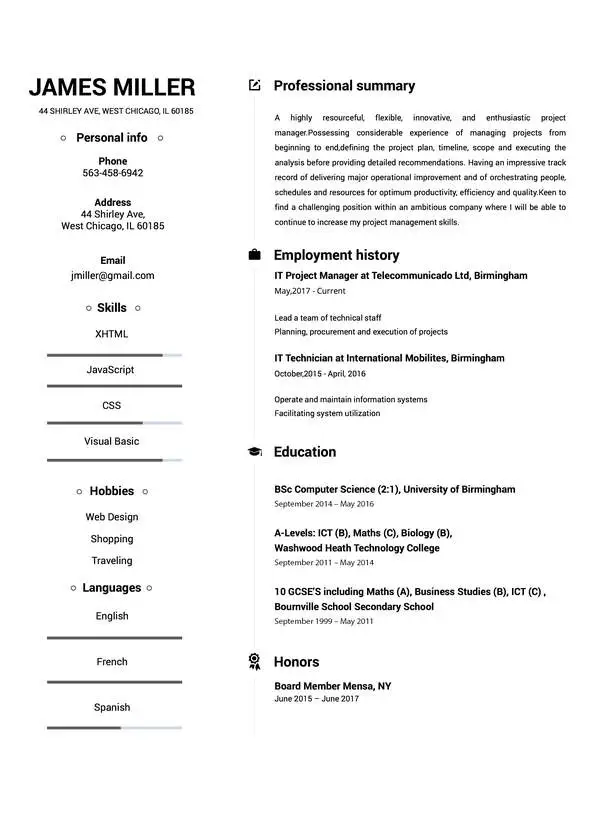

Let’s analyze the next couple of quality engineering resume samples.

2 quality engineer resume summary examples

This is a job description, not a career summary.

This applicant has used their summary to write about their experience with a simple employer and at the same time not sharing anything particularly interesting.

Here we have an impactful message which demonstrates the applicant’s experience in the oil and gas industry.

They have worked with a high-profile project management software for pipeline projects.

It’s not mentioned, but you’d reasonably expect this quality engineer to have written reports regularly.

A recruiter will most definitely give this quality engineering resume a more detailed look.

Analogously, for student quality engineering resumes , applicants should focus on their education, making a connection between their degree and the job requirements.

The next quality engineer resume sample takes this into account. How different is it from your resume?

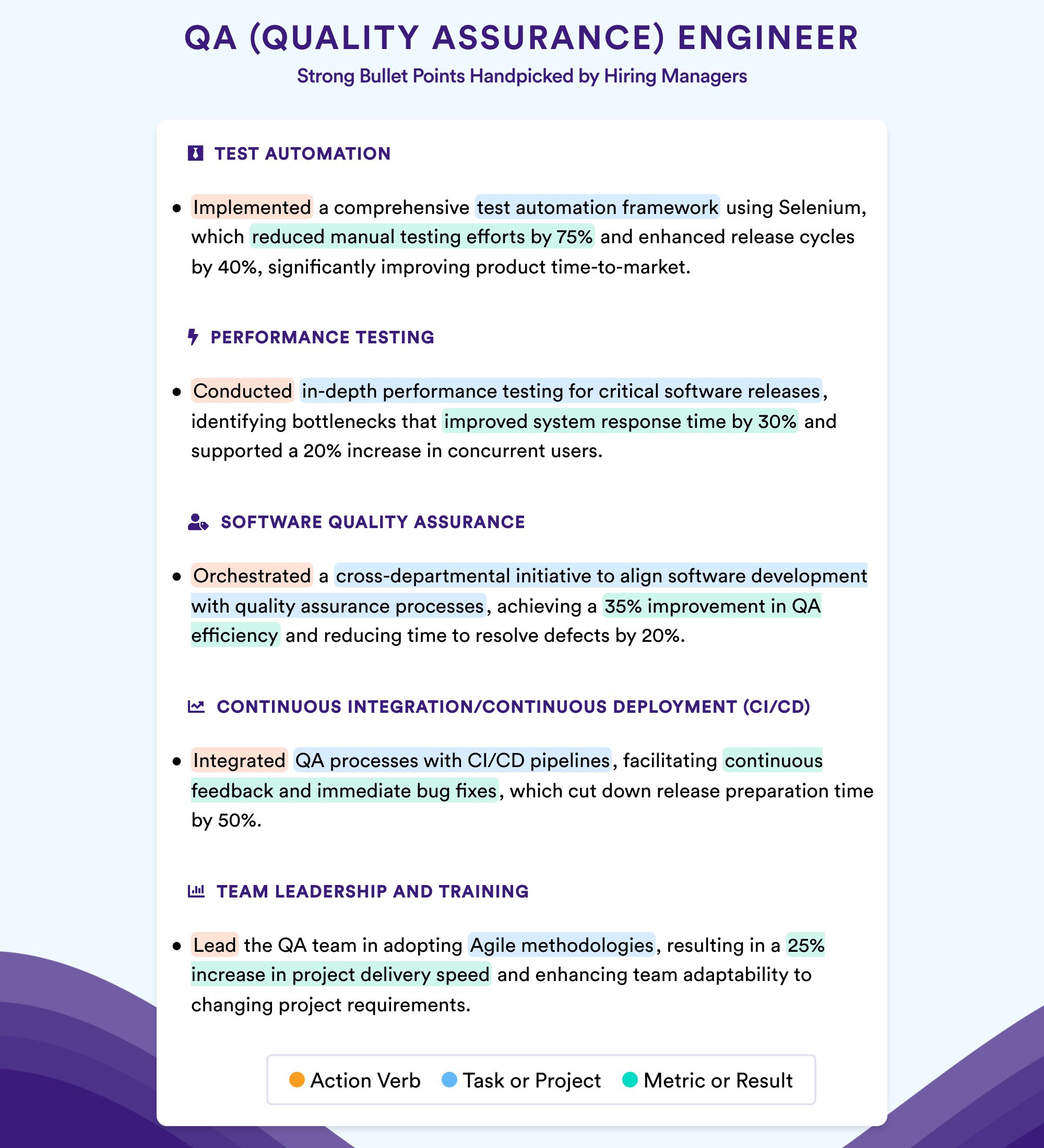

You’ve made a fair amount of claims in your professional summary.

Now that recruiters have reached your work experience section , they will expect to see strong arguments.

Quality Engineers treat their work experience like a SOP - detailed descriptions of their responsibilities and daily work.

That’s not at all what recruiters want to see.

Your hiring manager knows very well what the inspection and testing process involves. They’ve seen quality reports before - probably more than you have.

Instead, you want to show them the results:

- What value did you bring to your last company?

- What quality improvements have you implemented?

Use facts and figures from your job:

- How did you solve a production bottleneck at the stamping press?

- Have you retrained operators to use a more effective production sequence?

- Were you able to cut down the total cost by reducing scrap?

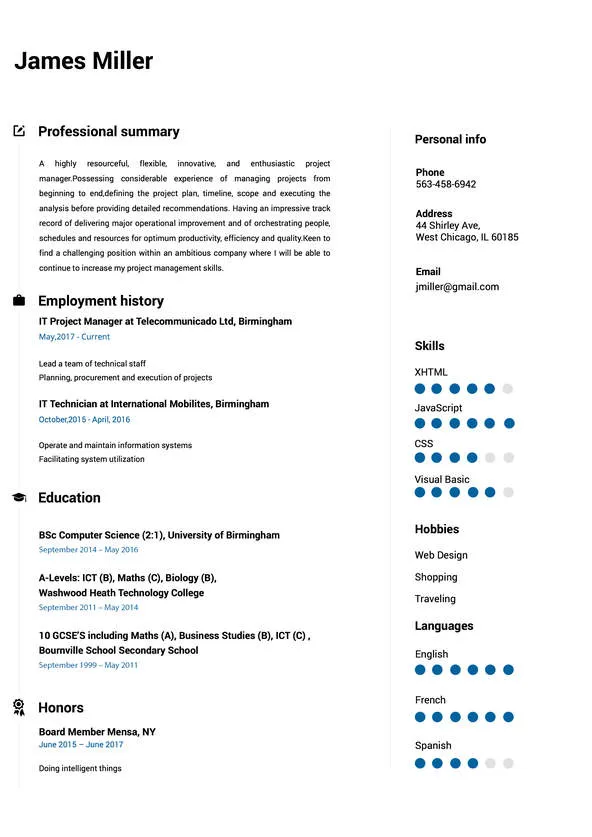

Quality engineer resume experience examples

- • Quality control on the production floor

- • Inspected production after manufacturing to ensure standards are met

- • Collected quality and performance data and compiled reports for upper management

- • Helped machine operators resolve problems

- • Participated in quality review meetings by management to provide insight on the production process and the problems requiring immediate action

Are they a real engineer?

The work experience listes their title as a "quality assurance specialist". There’s nothing wrong if they moved up from an operator to a QC position.

However, an engineering position will most certainly require a bachelor’s degree as a minimum. Your recruiter might think you don’t have the necessary qualifications for the job.

The last thing you want is to confuse them and make it hard for them to understand your experience and skills.

- • Designed testing procedures and quality control processes for the petrochemical industry

- • Conducted lab tests to ascertain composition of products - Reformulyzer, DHA, Specific gravity, Octane number, Sulfur content, etc according to ASTM and ISO quality standards,

- • Used Six Sigma to identify and eliminate inefficiencies in the production process.

- • Reduced production time by 2% by suggesting the use of hoists in critical areas to operators lift heavy bags of materials into the hoppers.

- • Prepared full suite of documentation regarding quality assurance and control - quality plans, SOPs, test reports, using VelocityEHS.

- • Automated chemical analysis dashboard universally accessible by all higher managers. Real time status reports available every morning.

This candidate has done a great job writing their work experience. It’s structured well and packs a ton of information.

The title is relevant to the job offer.

The candidate opens with the industry they work in to remove all doubts.

Most importantly, they demonstrate commitment and passion to improve the process. They have created value for their employer.

That’s the kind of QA Engineers companies are looking for.

Get this right, and you can expect a phone call very soon.

It’s difficult to write about your work experience when you’re still in school or just cleaned out your dorm room.

There’s just not a whole lot to add. Or is there?

Read the job posting carefully and make a note of all requirements - education, engineering aptitude, software use, hard skills, soft and interpersonal skills.

Try to analyze what expectations they have from successful candidates.

Now, work your way through your own skills and experiences and find items which will match the job description.

Focus on them and fill the gaps with additional skills and experience you think are valuable.

That alone, coupled with the tips below, should give you a competitive edge over the rest.

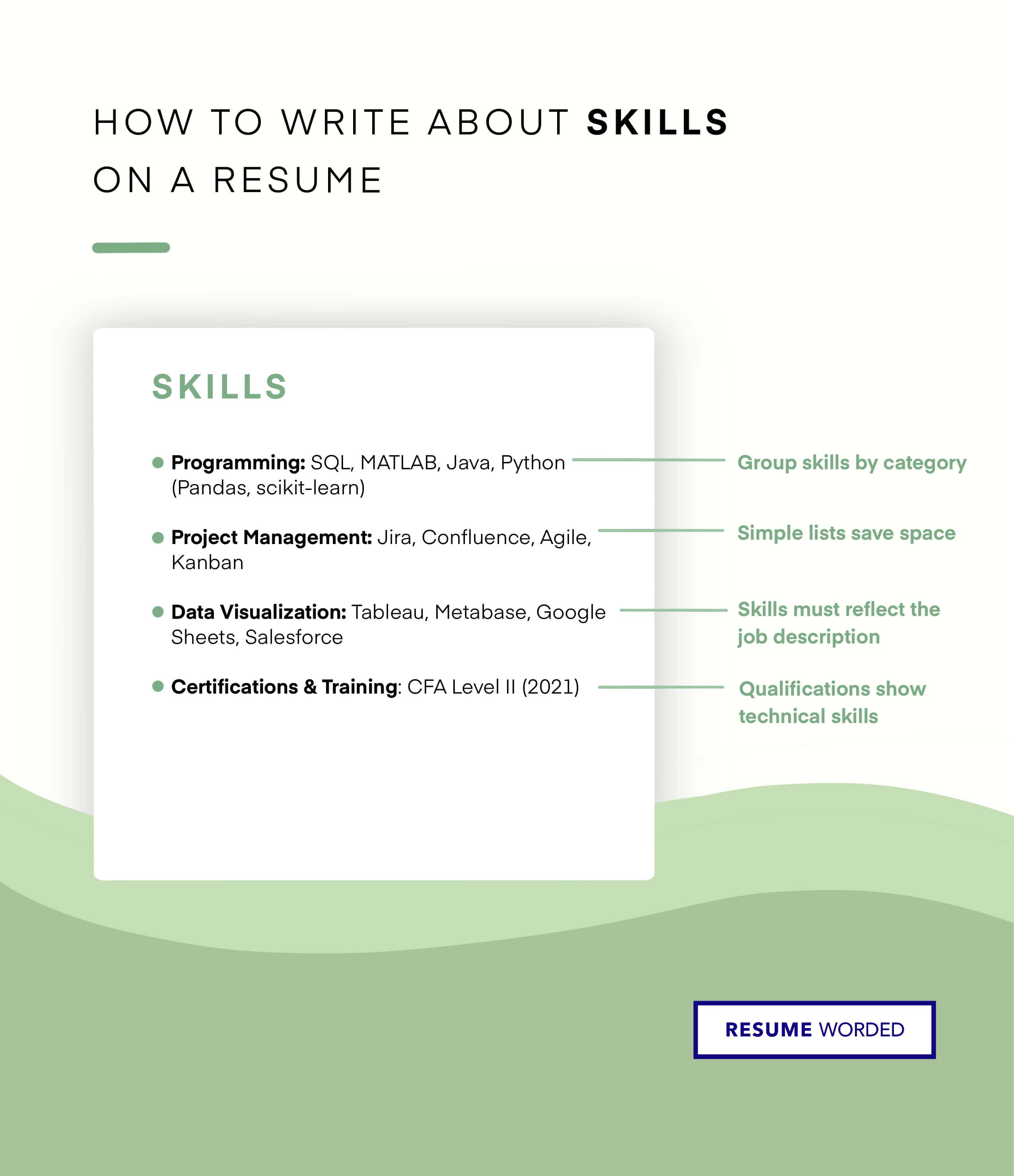

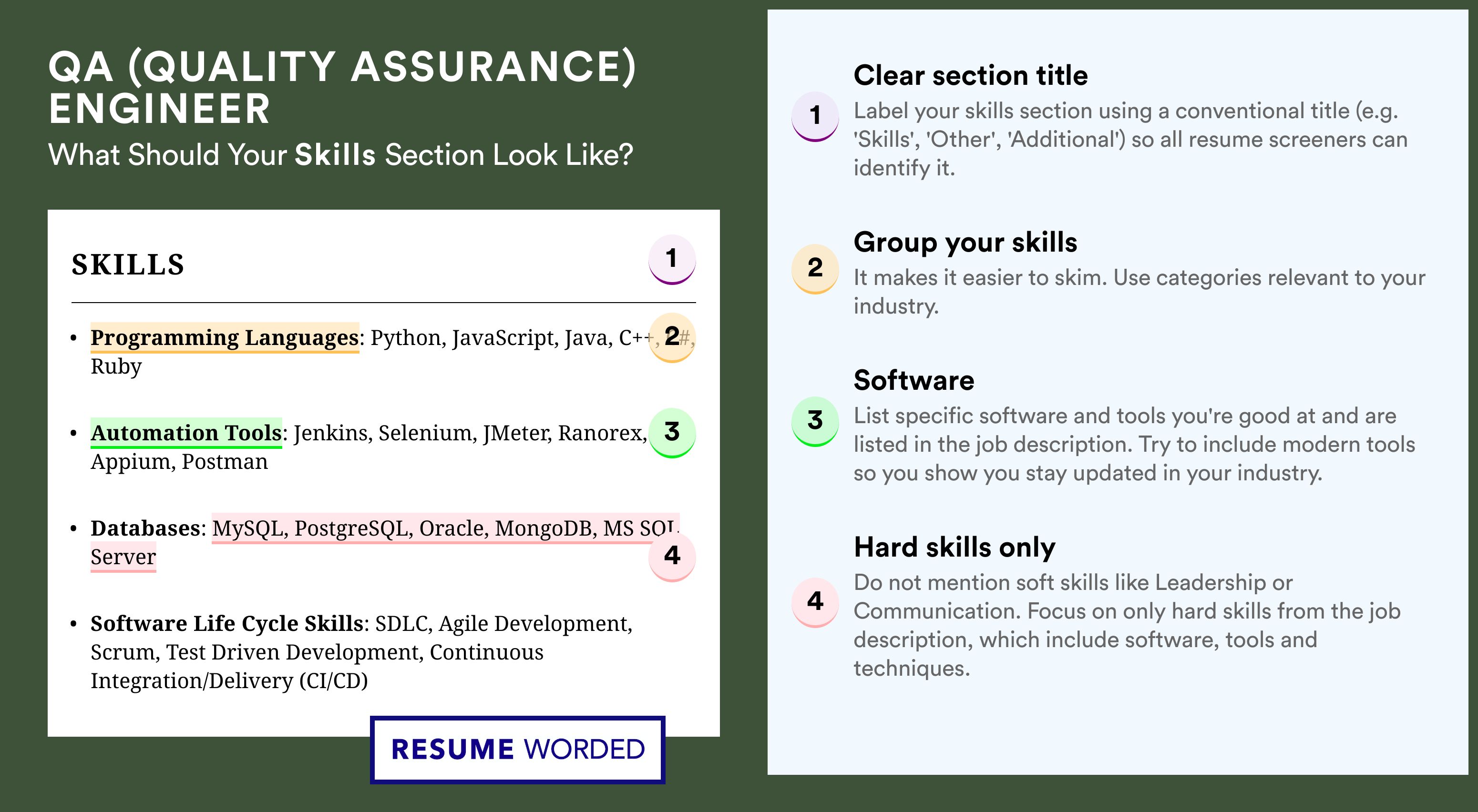

We already discussed how to position critical skills in every section of your resume.

However, a dedicated skills section helps tracking software scan and validate your resume.

Large organizations which receive thousands of applications frequently employ such tools to remove the ones that don’t match their desired profile.

We’ve added a couple of great quality engineering samples below to help you discover ideas for your own resume.

How to position your tech skills

The skills listed in your quality engineering resume will largely depend on your particular industry and job offer.

Below we’ve collected a small pool of technical skills you may find relevant to the job offer.

Top 10 technical skills for quality engineer resumes

- Quality control and project management strategies

- Lean manufacturing

- Lean Six Sigma

- ISO 9001:2015

- Total Quality Control

- Deming's 14-Point Philosophy

- Reliability engineering

- Quality control tools

- Pareto chart

- Fishbone diagram

- Six Sigma 5S

- 8D Methodology

- Quality management software

- IntraStage BlackBelt

- ComplianceQuest

- The Lean Machine

- Manufacturing

- Cutting tools and equipment

- Hot and cold forging

- Injection moulding

- Mechanical engineering

- Strength of materials and material science

- Fluid dynamics

- Thermodynamics

- Electrical engineering

- Electromagnetism

- Power generation

- Industrial automation

- Semiconductors

- Electronics

- Circuit design and analysis

- Printed circuit boards

- Programing and software development

- Chemical engineering

- Nuclear engineering

- CAD software

- Data processing and analysis tools

How to frame your soft skills

Excellent technical abilities are a prerequisite for becoming a Quality Engineer.

You need to understand beam loading scenarios and not be afraid to take out the calculator.

However, this is not what you’re expected to do on a daily basis.

Your work is with the people - the ones who do the math and push the buttons.

It’s your job to help them do their jobs better and yield a superior product.

So, when you talk about your soft skills, support them with actual examples from your work history.

This is a much better way of talking about them rather than just simply stating them.

Check out the table below and add all relevant soft skills to your quality engineering resume.

What soft skills should your quality engineer resume have?

- Analytical thinking

- Problem solving

- Practicality

- Time management

- Attention to details

- Communication skills

- Organization

- Project management

- Proactivity

- Reliability

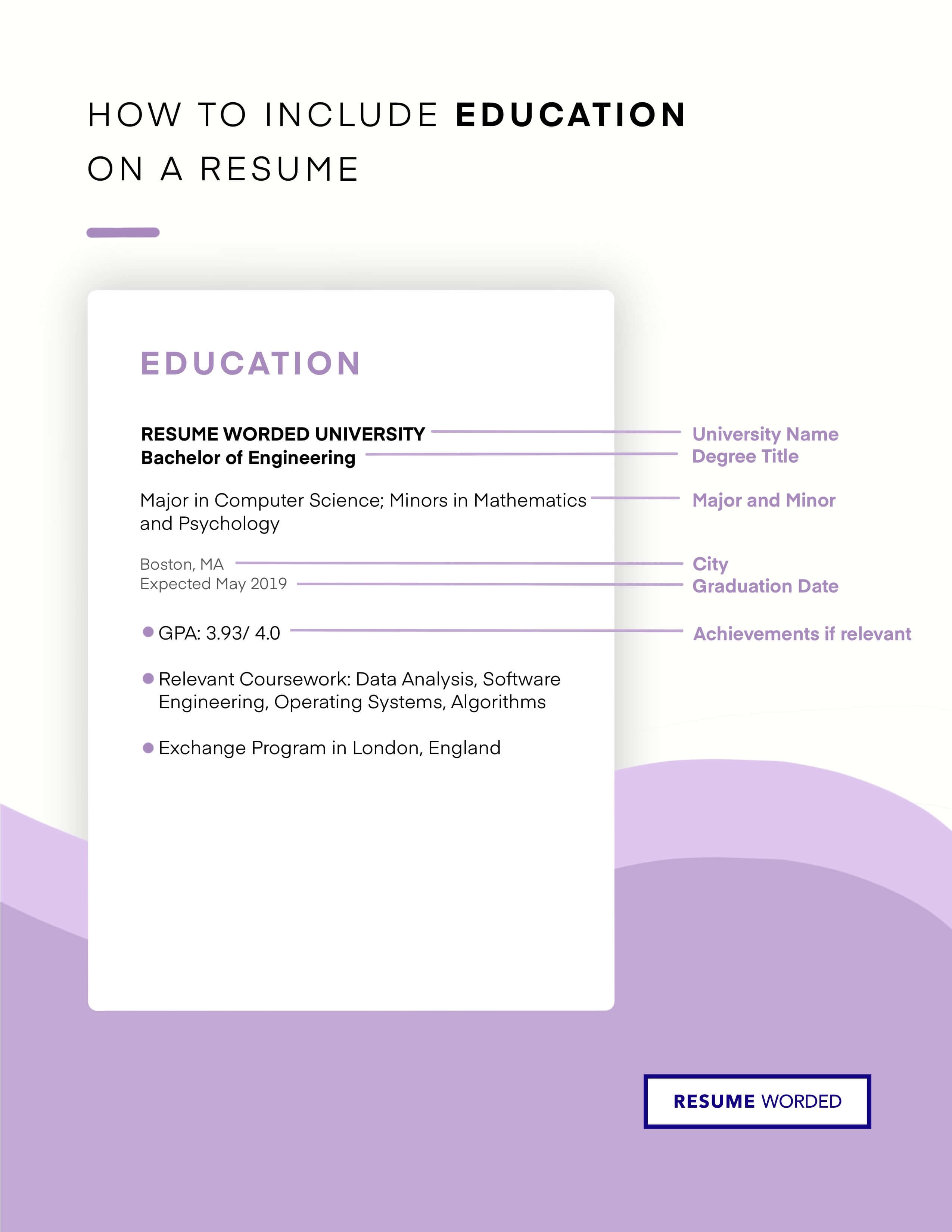

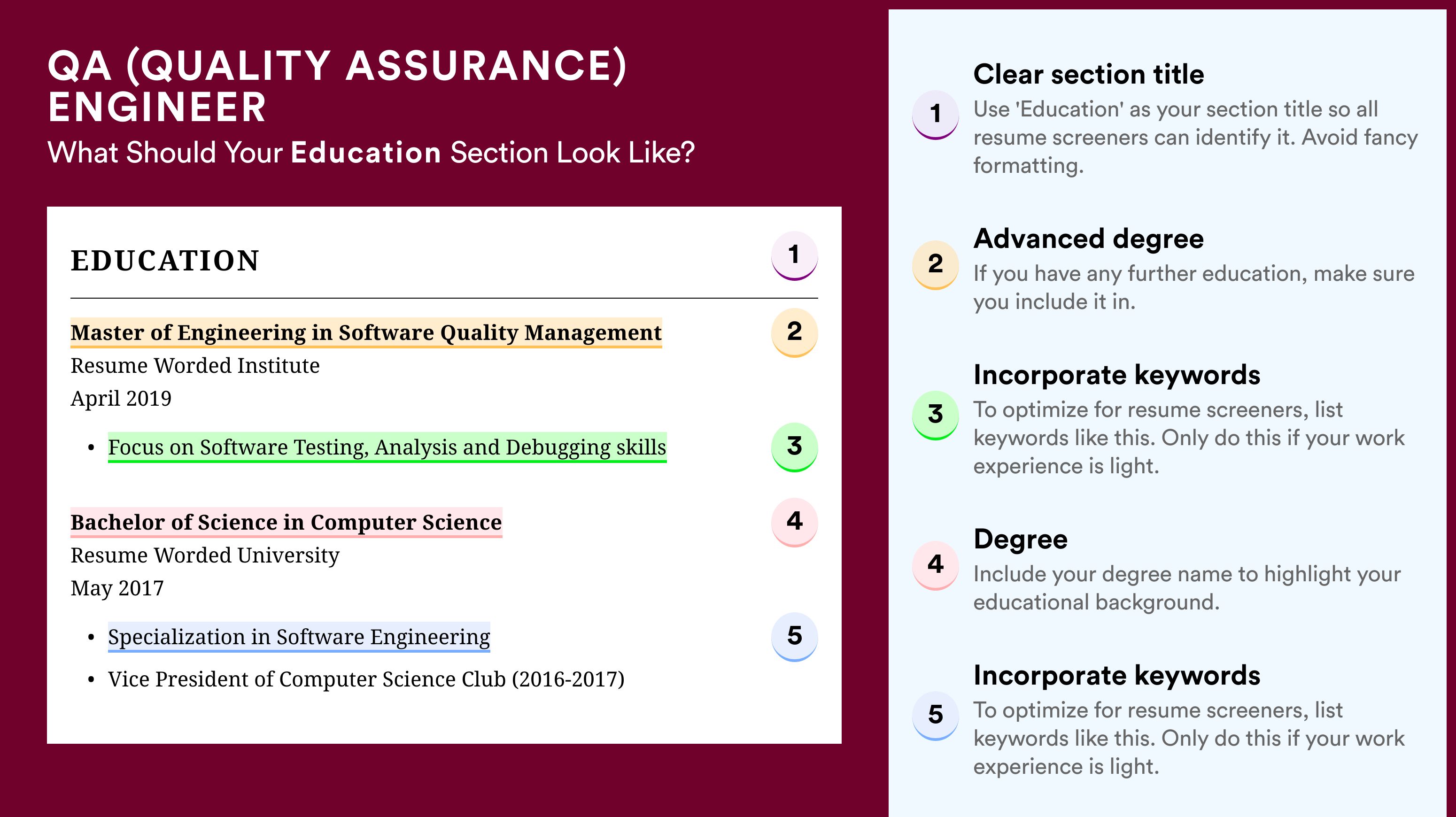

Fewer Quality Engineers graduate with that exact title.

If you have one, make sure the emphasize it in early on in your quality engineering resume.

It’s a huge asset, giving you an edge over candidates who learned quality assurance while on the job.

Most Quality Engineers obtain a traditional engineering degree and start their professional life in other roles within their industry.

Whatever your diploma is, you should list it in a dedicated education section along with a few critical details:

- Engineering title

- Year of graduation

- GPA if great , skip if not

- Institution

If you’re a student, you may want to expand a little bit on the courses that are relevant to the job offer.

In general, don’t focus too much on your degree - thousands of other people have it and it’s hardly the X factor recruiters are looking for.

In case you don’t have formal QA/QC training, you want to think about professional certifications . They will close the gap and give your management and QA skills some backup.

Some of the certificates listed below are invaluable and may be worth more than an engineering degree from the perspective of your employer.

Consider obtaining one if you don’t have a lot of experience in quality assurance and control.

The following list includes the most wanted quality engineer certificates on resumes

- American Society of Quality Certification

- Lean Six Sigma Green Belt

- FMEA Certification Exam

- PMP Project Management Professional

- SAP Certification

- FE / PE Certification

- Focus on the skills, experience and knowledge most relevant to the job offer

- Emphasize them in every section of your resume and use the same language and keywords found in the job description

- Triple check your resume header - even a tiny mistake can send your application to the shredder

- Don’t mistake the career summary for a job description. Use impactful language to persuade recruiters to keep reading

- Use your work experience to demonstrate you have been a valuable asset to your employers

- Add a well organized skills section which is relevant to the job. Edit and reorder when applying to different job offers

- Don’t forget about your education and certifications. Add a dedicated section that’s easy to locate and read.

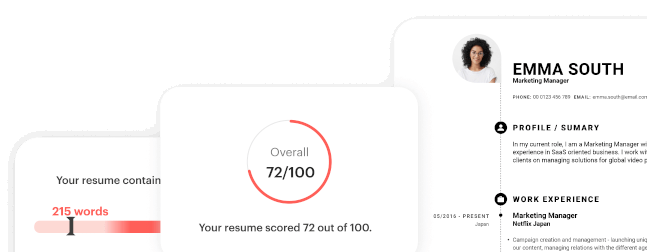

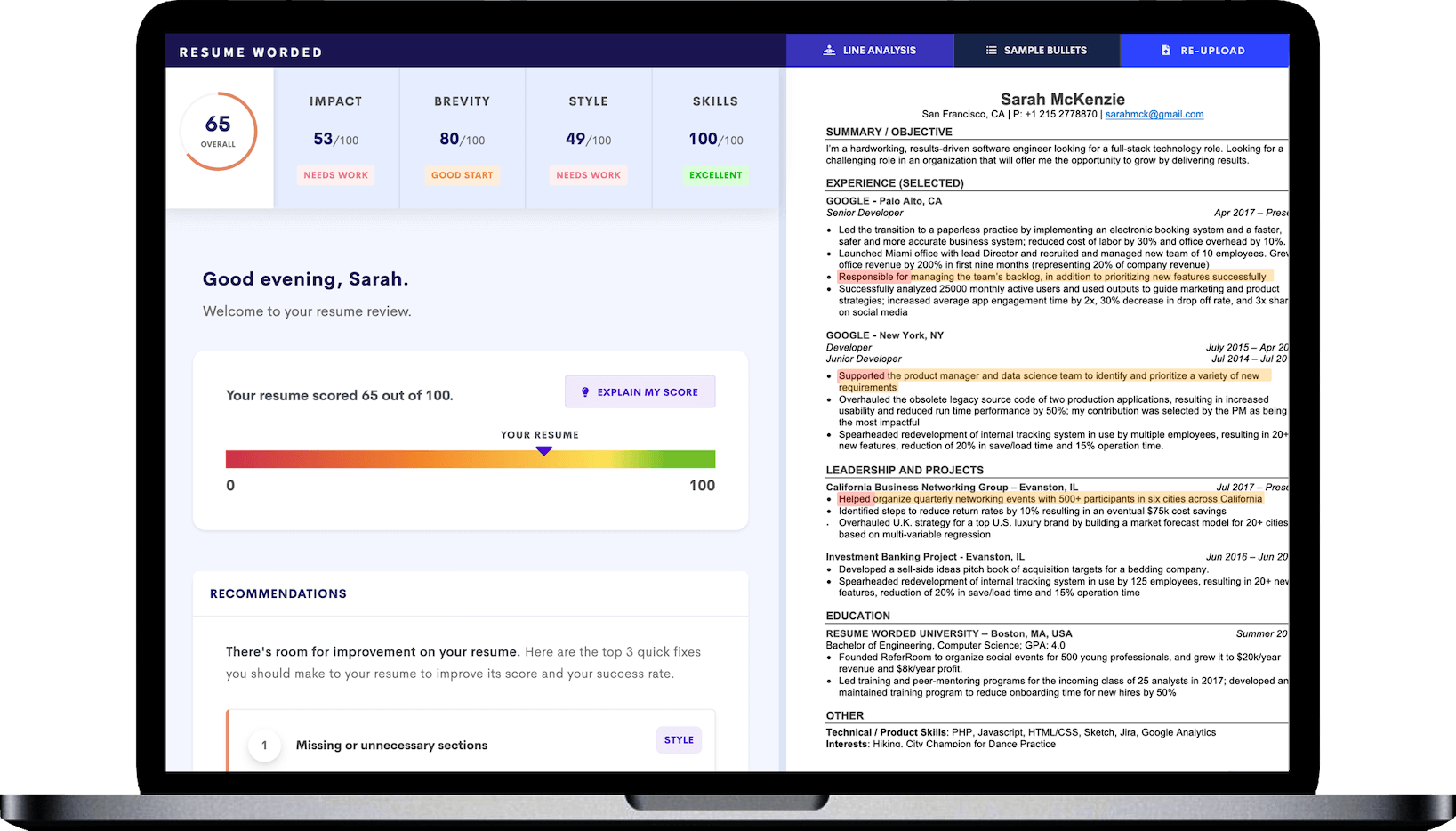

Looking to build your own Quality Engineer resume?

- Resume Examples

Cover Letter VS. Resume –What's The Difference?

Spot the red flags: how to know if a job is a scam, why are you leaving your current job - interview question (+ answers), how to answer the “are you a team player” interview question, how to organize your resume in 2023 [+ resume examples], 5 things we learned from helping 249 engineers write their resumes.

- Create Resume

- Terms of Service

- Privacy Policy

- Cookie Preferences

- Resume Templates

- AI Resume Builder

- Resume Summary Generator

- Resume Formats

- Resume Checker

- Resume Skills

- How to Write a Resume

- Modern Resume Templates

- Simple Resume Templates

- Cover Letter Builder

- Cover Letter Examples

- Cover Letter Templates

- Cover Letter Formats

- How to Write a Cover Letter

- Resume Guides

- Cover Letter Guides

- Job Interview Guides

- Job Interview Questions

- Career Resources

- Meet our customers

- Career resources

- English (UK)

- French (FR)

- German (DE)

- Spanish (ES)

- Swedish (SE)

© 2024 . All rights reserved.

Made with love by people who care.

Resume Builder

- Resume Experts

- Search Jobs

- Search for Talent

- Employer Branding

- Outplacement

- Resume Samples

- Quality Assurance

Quality Engineer Resume Samples

The guide to resume tailoring.

Guide the recruiter to the conclusion that you are the best candidate for the quality engineer job. It’s actually very simple. Tailor your resume by picking relevant responsibilities from the examples below and then add your accomplishments. This way, you can position yourself in the best way to get hired.

Craft your perfect resume by picking job responsibilities written by professional recruiters

Pick from the thousands of curated job responsibilities used by the leading companies, tailor your resume & cover letter with wording that best fits for each job you apply.

Create a Resume in Minutes with Professional Resume Templates

- Analyzes and resolves work problems, or assists workers in solving work problems

- 7)Assist Quality manager in establishing, implementing and maintaining the quality management system

- Execute the development, implementation and continued improvement of the Quality Management Systems throughout the operation

- Work with engineers and product managers to create, implement, and improve QA procedures and Process

- Assist in development of quality system processes, i.e., records management and document control, control of electronic data, Quality Site Management

- Assists the Quality Manager and the Assistant Quality Manager with day-to-day plant issues

- Maintain performance management KPI’s and board and participate in performance management meetings

- Assisting Quality Engineering management and other functional managers to implement and develop process and product improvements

- Performing an active role in further development and continuous improvement of the quality management system

- Analyzes and develops suppliers products to obtain maximum productivity and reviews performance in operation and provides suggestions for improvement

- 3) Assist Quality Manager in project work related to core production. Raise potential quality/compliance issues to management

- Assist in the development and improvement of the Product Excellence Management System

- Actively monitor the effectiveness of processes and quality of project work with management, and propose and execute quality/process improvements

- Analyzes and develops supplier’s products to obtain maximum productivity and reviews performance in operation and provides suggestions for improvement

- Good product knowledge and/or ability to grasp process and product knowledge quickly

- Excellent analytical, statistical and problem solving skills working knowledge of Data Visualization using Tableau, JMP, Minitab are highly desirable

- Strong analytical ability to solve programs and ability to learn quickly

- Ability to work proactively with suppliers to improve product quality and quickly resolve quality issues

- Strong computer skills and ability to learn technical software. Proficient in Microsoft Office suite of programs with strong Excel skills

- Basic knowledge of automotive quality systems (APQP, PPAP, Gage R&R, Process Capability)

- Basic Knowledge of assorted quality tools and standards (Gage R&R, Capability, PFD, PFMEA, PCP)

- Ability to work with a number of Quality scanning tools, be able to baseline and measure on-going quality metrics, and display via Dashboards

- Demonstrated record of some project accomplishments, knowledge of quality management systems, knowledge of organized methods to make systems predictable

- Ability to learn quickly and thoroughly while still being able to adapt quickly to change

15 Quality Engineer resume templates

Read our complete resume writing guides

How to tailor your resume, how to make a resume, how to mention achievements, work experience in resume, 50+ skills to put on a resume, how and why put hobbies, top 22 fonts for your resume, 50 best resume tips, 200+ action words to use, internship resume, killer resume summary, write a resume objective, what to put on a resume, how long should a resume be, the best resume format, how to list education, cv vs. resume: the difference, include contact information, resume format pdf vs word, how to write a student resume, quality engineer resume examples & samples.

- Support global pre-production test environments

- Industry experience of client facing roles within the financial services industry

- Approximately 5-7 years’ relevant experience

- Experience working on Shell/Perl and Python

- Experience working on relational database (oracle, sybase, udb)

- Experience with java / c++

- Experience working with Agile methodology

- Ability to work in an independent manner with minimum supervision

- Excellent problem solving and analysis skills

- Ability to manage multiple projects with differing priorities

- Atlassian JIRA / Greenhopper / Subversion

- Messaging experience

- Lonsched / Autosys or Control M experience

- ITIL v3 Foundation Certificate in I.T Service Management

- Interprets drawings featuring Geometric Dimensioning & Tolerancing (GD&T) per ASME Y14.5 to identify product inspection requirements

- Writes and edits programs utilized in manufacturing PC-DMIS, COSMO & CALYPSO, etc

- Serves as technical expert for metrology inspection

- Facilitates, encourage and coordinate continuous improvement with respect to inspection activities

- Set-up data collection parameters for inspection measurements where required

- Installation of inspection assets as to follow local validation lifecycle

- Develops inspection strategies to meet business needs

- Development of new inspection techniques as required

- Development of standard platforms where applicable (vision systems, contact/non-contact inspection systems

- Develop method of "gauge" evaluation to consider, calibration frequencies, gauge life, fit for purpose, etc

- Generates the inspection report per the customer requirements

- Performs 1st Article inspection of newly developed product

- Site lead on development of inspection fixturing to ensure minimum measurement error during inspection

- Inspect complex machined fixtures, and parts using advanced measuring and layout instruments and equipment

- Participates in design reviews on cross-functional teams to ensure that conformance to specifications, inspect ability, reliability, and quality system objectives are met

- Assist engineers with qualification and validation of new or changed tooling or parts

- Prepare detailed inspection documentation such as written descriptions of inspection results including deviations from engineering specifications

- Work from written or verbal instructions, detailed engineering drawings, and 3D models

- Writing of work instructions for inspection techniques relating to standard platforms for associates

- Development of validation approach in conjunction with QA for all inspection platforms

- Training of QA/Manufacturing personnel to execute measurement method/equipment

- Responsible for supporting the activities of Operations / Engineering / Information Management in building product Quality into our products and assuring compliance to the pertinent regulations while at the same time attaining operational effectiveness

- Work with the various departments/groups in development and execution of validation activities associated with new equipment/product or I.M. system upgrades

- Runs /Manages complaint investigation and resolution of same

- Designs and develops validation documentation to support business continuity, new process introductions

- Implementation and co-ordination of the change control process, promotes timely approval of all supporting documentation

- All employees are responsible for minimizing both the Environmental and Health & Safety effects of the work that they perform

- Overall responsibility for production GMP standards and compliance

- Investigation of root cause and following through on effective corrective actions to prevent re-occurrence for customer and internal quality issues

- Establishing and maintaining FMEA's

- Preparing and updating Operations procedures and associated documentation

- The quality engineer will perform an active role in quality planning and new product introduction from a quality perspective

- Develop strong links with customer organisation's and other project stakeholders

- Quality review of responsible area validation documentation

- Identify and implement effective process control systems to support the development,qualification and on-going manufacturing of products to meet or exceed internal and external requirements

- Direct Involvement in operations area projects and initiatives i.e Six Sigma improvements,Lean etc

- Develop and implement quality metrics and reporting systems

- Preparation of Quality reports for Quality meetings and management reviews

- Take a lead in the implementation of process controls and CAPA systems designed to meet or exceed internal and external requirements

- Acts as an effective team member in supporting quality disciplines, decisions and practices

- Apply sound, systematic problem solving methodologies in identifying, prioritizing,communicating and resolving quality issues

- Ensure regulatory compliance to GMP for all regulatory agencies

- Suggest changes in procedures and standards to facilitate work efficiency and maintain quality

- Reporting Functional area Quality Metrics

- Perform an active role in quality planning and new product/process introduction

- Conduct internal quality audits to ISO and GMP requirements

- Min 4year industry experience in a medical device manufacturing

- Science/ Engineering/Quality Degree and relevant experience

- Previous experience within the medical device industry in Quality / Engineering is essentialas is demonstrated use of Quality tools/methodologies including Six Sigma techniques

- Knowledge and Experience of Statistical Process Control would be beneficial

- Excellent Computer Skills (word, excel, powerpoint and Access)

- Excellent communication (both verbal and written) & interpersonal skills

- Flexible, highly motivated individual and accountable

- Direct supervision of all personnel in IQC and Product release

- Co-ordinate daily IQC activities to ensure production requirements for raw materials are met

- Ensure regulatory compliance to GMP's of all medical device regulatory agencies (eg, FDA, ISO and MDD)

- Drive changes in procedures and standards to facilitate work efficiency and to maintain quality

- Support Strategic Supplier Initiatives and Corporate Supplier Quality Initiatives in relation to IQC activities

- Review of change requests to evaluate each change for quality related issues

- Manage and perform compliance tests both internally and externally

- Co-ordinating effective and timely follow-up on all supplier quality issues where appropriate

- Support new supplier qualification initiatives and high risk component issues when required

- .Drive the development and implementation of test and inspections methods for raw materials and components

- Works with manager to establish department goals and accountabilities

- Assists manager in planning resource needs and hiring

- Support the quality manager in the implementation and maintenance of the compliant quality system in the Limerick site

- Maintain equipment calibration schedule and records

- Write and maintain quality standards and procedures

- Be responsible for ensuring the production and release of quality products in compliance with all manufacturing procedures

- Be responsible for writing NCR's and supporting the resolution of internal and external non-conformances

- Provide quality representation on new product development teams

- Ensure and maintain the quality supply of raw material and components through the quality system controls

- Train all staff in ISO, GMP and other Quality Systems training

- Perform duties in accordance with BD policies & procedures & GMP regulations

- A minimum of 3 years' quality experience in an instrument development and production industry including expertise in ISO 9001, ISO 13485 and 21 CFR Part 820

- Auditor experience beneficial

- Excellent communicate and interpersonal skills enabling effective cross functional and cross site teamwork

- Effective skills in analytical thinking and problem solving

- Ability to work in teams to obtain results, self-motivated/directed, ability to organize and supervise people and activities, minimal supervision required

- Knowledge of manufacturing processes and relevant statistical techniques

- Understanding of continuous improvement methodologies including lean, six sigma, and validation

- Ability to operate effectively within a team environment and work across functional and organizational boundaries

- Demonstrated ability to implement quality improvement tools in a team environment

- Must possess demonstrated project management skills, including a proven track record and demonstrated ability to effectively drive projects to completion

- Collaborating with all levels of Production, NPD, and Supply Chain

- In conjunction with NPI manufacturing engineer access existing manufacturing capabilities for defined project needs. Manage gaps, risks, and RCA and drive resolutions

- Support the robust delivery of new product development DP’s with a high focus on DP Ops stage

- Drive quality communication related to new products to ensure knowledge is shared and recorded

- Occasional contact with current and potential customers of Global Faucets regarding product related performance, process control & capability, as well as improvement opportunities

- This is an entry level engineer position

- Performs the tasks described for assignments of a global scope with some direction from their manager. This individual should enjoy being a change agent and a management planner with the capability of applying fundamental quality techniques in multiple projects globally, and shall be actively developing skills in product, process and system improvement techniques

- Excellent oral & written communication and computer skills with Microsoft Office Products are needed

- Establish and manage appropriate quality tracking mechanisms within the operations area to drive improvement based on real time data

- Utilize above mentioned quality data to prioritize issues to be addressed and lead / collaboratively work with all functions to establish true root cause and irreversible corrective actions

- Make appropriate cross functional decisions using quality analysis tools and critical thinking including cost / impact analysis and customer impact

- Lead in the development and maintenance of control plans and inspection instructions

- Develop and maintain appropriate controlled area for non-conforming material

- Daily production line support by making daily decisions related to product quality; serving as the voice of the customer

- Participate in safety, cost, and delivery improvement initiatives

- Participate in new product launch activity and training

- B.S. with exposure in statistics and engineering terminology and total quality management

- 0-5 years in the quality field

- Proficiency in data collection and statistical analysis

- Ability to effectively interface with manufacturing

- Strong written and oral communication skills. Must possess strong verbal and written communication and presentation skills

- Ability to communicate cross functionally internally/externally as well as to all levels of the organization

- Must be able to manage and drive change

- Must be able motivate others

- Technical support for final production processes and deliveries of our stationary storage systems

- Direct customer liaison for technical and organizational inquiries from our partners

- Debug systems and perform diagnostics on field failures both remotely - looking at data logged by the systems, and directly in the field as needed

- Perform root cause analysis and help determine if design changes are required

- Work with engineering and manufacturing teams to ensure new issues are fully investigated and that countermeasures are in place

- Recognize trends and patterns in field failures and provide feedback to drive future designs

- Develop and document procedures for use, handling, charging, storage, shipment of high voltage batteries and grid-tied systems

- Install and diagnose complex mechanical/ electrical systems at customer sites and deliver training to technicians

- Support technicians in the field with troubleshooting techniques and remote diagnosis, occasionally travel to perform field diagnosis or repair

- Represent Quality as part of a cross functional team to ensure delivery of projects (NPI's and Technology) into production with the highest level of quality, compliance, and adherence to timelines

- Compile and execute validation protocols for new product/processes and software. Ensure correct implementation as per standard validation procedures. Re-validate as required due to engineering change, deviation analysis or upgrade in systems and material

- Use of statistical analysis as part of validation activity and defining subsequent inspection and controls in production

- Develop and utilise DFMEA/PFMEA and other QA risk analysis techniques in order to minimise potential risk during development/implementation activity

- Liase with R & D to ensure Critical to Quality Characteristics are agreed and documented for all New Product Development

- Lead Design for Inspection activities for all New Product Introduction to ensure latest technology is available to reduce Human Error

- Lead QA input to Design for Manufacture activities on site

- Ensure daily and project compliance with all Documented Quality systems i.e. FDA QSR's and ISO 13485/9001 requirements etc. during all day to day

- Provide technical assistance to carry out problem analysis/complaint investigation as required and define through negotiation effective corrective actions

- Assist in problem solving for new products and established production process enabling reduction in compliance risks, scrap and reprocessing

- Assist in the development, review and approve product, gauge, tooling and fixturing drawings

- Maintain a good level of house-keeping in designated areas, and observe all Health and Safety at work requirements

- Reviews and evaluates product and solution designs and production activities for potential quality issues; provides tangible feedback based on results and root-cause analysis and designs and implements solutions to improve product quality and mitigate risk of failures

- Bachelor's or Master's degree in Industrial Engineering, Manufacturing Engineering, Electrical Engineering, or equivalent

- Lean, Six Sigma black belt or equivalent preferred

- Extensive experience with using engineering tools and software packages to test, design, and evaluate products and processes

- Evaluating forms of empirical and root-cause analysis, modeling, testing methodologies, and quality standards to validate product designs, specifications, and processes

- Implements and assists with designing portions of quality requirements, processes, and practices into the development, design, manufacturing, and continuous improvement of portions of a product or solution

- Collects, consolidates, and charts data from reports, testing, and process results for assigned portions of components to identify trends and issues; learns and practices basic root-cause analysis

- Develops understanding of and relationship with internal and outsourced partners for product development and manufacturing

- Experience or understanding of engineering and testing tools and software packages

- Good analytical, statistics, and problem solving skills

- Basic understanding of material properties, hardware and electrical component design and manufacture, and industry quality standards and methodologies

- 3-5 years of full-time software testing work

- Practice with building correctness, performance, scalability, and durability tests

- Work with systems that process gigabytes of data daily and archive terabytes of history

- Scripting to package, install, deploy and run multi-node tests across a database cluster

- Testing complicated applications against thousands of UI clients or hundreds of millions of events and billions of rows of raw data

- Proven ability to create test strategies and implement test cases

- Practice with real-world deployment of customized software built for a specific market or application

- Strong analytic and logic reasoning skills

- High desire to learn and strong learning skills

- Strong English verbal and written communication skills and good team player

- Capable of taking tasks from beginning to end independently

- Developing NDE inspection procedures for quality issues where parts need to be quickly sorted for defective versus non-defective. Must be capable of developing inspection procedures for mag particle, ultrasonic, Eddy current, and dye penetrant inspection equipment

- Organizing and training lab technicians on short notice for 100% inspection of parts to address quality issues

- Oversight of daily metallurgical inspection procedures done in the lab - i.e. movement of material, prioritization of the workload, daily assignment of technician staff to do the required inspection work, etc.

- Communicate to and advise other LECU facilities on NDE issues in particular the Tianjin facility that will start building 3500 engines in 2015

- Meet with auditors from Marine Societies and ISO during their visits to the facility to answer any questions concerning quality inspections done on critical engine components such as crankshafts and connecting rods

- Certified Level 3 NDE from ASNT

- Minimum of 3 years work experience in materials engineering

- Good interpersonal skills to develop a cooperative working relationship with technicians who work in the lab as well as engineers who are customers of our lab work

- Good teacher as new production technicians need to be periodically trained and certified for mag inspection

- Effective delegator and ability to manage multiple projects

- Positive attitude and a sense of urgency for completing tasks especially during quality issues where development of a reliable NDE inspection technique is critical

- Good analysis, diagnostic and judgment skills

- Bachelors degree in materials engineering with emphasis on ferrous metallurgy

- Prior experience working in a manufacturing environment, or in the quality field

- Work with team to meet the ISO9000 & Caterpillar QMS certification requirement

- Using basic statistical techniques to analyze and report trends in product test results. These results determine if current tests have customer value, improvements or deterioration in quality levels and possible changes in test procedures or specifications

- Requesting tests to be run, analyzing the results, writing and issuing Quality Control Inspection

- Bachelor degree of Mechanical Engineering or related

- At least 3 years quality related experience

- Overall knowledge of ISO9000 certification

- Good English and Mandarin communication skill

- Possess imagination and creativity to formulate new ideas and initiative to follow up and develop ideas

- Familiar with Caterpillar QMS system

- Performs Quality Assurance for a business division by performing product test procedures, validating product specifications, performing audits, and leading product reliability improvements via Caterpillar’s New Product Introduction program and Continuous Product Improvement programs

- Develops plans and tools to support quality systems and related processes for a business division. The incumbent provides support for quality programs and certifications, as well as Lean Manufacturing and systems implementations

- Supports business division employees tracking continuous quality improvement projects and a quality scorecard, leading internal quality programs, developing related training programs, conducting internal quality audits and facilitating management reviews

- 4-year degree in an engineering or manufacturing-related discipline (or equivalent)

- Minimum of 3 years of relevant work experience

- Thorough knowledge of relevant quality concepts, certifications, processes and tools

- Strong communications, collaboration and influencing skills

- Ability to work with diverse teams of employees and customers

- Ability to effectively train / coach diverse groups about quality concepts, certifications, processes and tools

- Bachelor Degree in Mechanical Engineering, Industrial Management or related field

- 3 years’ experience in the quality function in a manufacturing environment

- Good knowledge in ISO 9001 and Core Tools such as PPAP, FMEA, SPC

- Good knowledge and skill in technical problem analyze e.g. 8D report, 5 Why Analyze, Control chart etc

- Good in problem-solving skills, analytic skill and decision-making

- Good in English language and computer skill

- 3) SDLC, Prior Testing/QA skills & knowledge of 3D graphics and Multimedia

- 4) Self-motivated and enthusiastic

- 5) Working culture of local & remote teams is a must

- 6) Strong knowledge of Windows and Linux

- 7) Strong analysis, problem solving & interpersonal skills

- 8) Experience with Test Automation FW and scripting knowledge

- 9) Flexible to work in shift basis

- 10) Good communication skills, attitude and results driven

- Support Quality Manger to setup and implement quality system with best practice in CWL by following Caterpillar Quality Management System (CQMS) and ISO9000 requirements

- Conduct and manage internal and external quality system audit

- Conduct quality system document management

- Track quality objectives and quality metrics

- Coordinate for corrective actions and improvement

- Analyze quality data to identify opportunities for improvement

- Support Quality Manager on other quality related activities

- College technical degree on engineering (mechanical engineering is preferred)

- 5 year work experience in manufacturing company (Automobile or construction machinery is preferred)

- Well understanding of ISO9001 and/or TS16949 and essential experience on quality management practice

- Work experience in a Europe or US company is preferred

- Minimum completion of post secondary education program in mechanical/quality engineering

- 3 to less than 5 years of work related experience

- Makes Decisions

- Attends to Details

- Plans, supports, and implements total quality programs. Defines scope, plans, organizes, leads and directs technical work and departmental efforts related to quality engineering activities for new and existing programs

- Designs, specifies, and installs quality control sampling systems, testing mechanisms, and equipment. Formulates and/or assists in formulating quality control policies and procedures and development of quality standards

- Monitors and controls costs, timing, and other related aspects of projects. Develops cost quotations related to specifications, test equipment, and gauge requirements and communicates information to appropriate parties. Understands and adheres to schedule and budgetary requirements of projects. Reports progress as required

- Serves as a liaison and coordinates activity of internal and external resources. Serves as a resource by providing a problem solving function by initiating action to overcome obstacles as they are encountered and prevent potential quality problems

- Demonstrated ability to conceptualize, coordinate, integrate internal data, and clearly articulate concepts, ideas, and other issues relating to advanced quality engineering

- Demonstrated creativity and ingenuity to work on moderate to long-term assignments which are broad in nature. Strong organizational, project management, and leadership skills to prioritize, coordinate projects, manage conflicting needs, and deal with many issues at one time. Must be able to work independently

- Demonstrated strong written and verbal communication skills in order to effectively communicate with internal and external contacts and represent the Company in a professional manner when performing job duties. Must have excellent interpersonal skills to exercise influence at various levels and functions

- Must be able to operate standard and specialized equipment related to the job. Strong computer background with ability to calculate and analyze data, generate reports, present information, etc

- Demonstrated ability to research and recommend new products and processes. Must be able to initiate implementation of continuous improvement processes

- Demonstrated ability to work on long-term assignments, broad in nature, using a high level of originality and ingenuity. Must be able to work independently with some latitude for unreviewed action or decision

- Demonstrated ability to lead and manage several large and complex projects simultaneously. Must have experience with past project financial responsibilities. Demonstrated ability to lead and motivate others through support, training, etc

- Demonstrated ability to thoroughly research, recommend, and oversee implementation of new products, materials, processes, etc. and present information

- Coordinate and manage all audits (internal, supplier, corporate, OEM customers)

- Review and approve changes to manufacturing processes, products, materials, and Quality System

- Promote and support multi-discipline teamwork, i.e., activities that support the Magna management system inclusive of vision, strategic initiatives and tactical plan

- Coordinate management review periodically to assess quality system

- Train others in implementation and maintenance of Magna’s internal quality systems

- Advanced skills in Quality methods (8D, 5 Why, etc.)

- Advanced skills in performing reviews and FMEA's

- Monitoring and enforcing the use of protective devices

- Responsible for following and reinforcing environmental and safety standards

- Monitoring shifts' beginning and end, as well as breaks, checking participants on continuous develpoment meetings

- Disciplinary authority, motivating employees

- Monitoring and updating employees' quarterly goals

- Responsible for quality and quantity of materials arriving to the area assigned

- Responsible for MQ and ISO measurements

- Supporting constant development with your team's ideas (T-card) and introducing and implementing them, especially safety precesses

- Takes part in RIW as well as CPS and 6 Sigma projects

- Managing documentations for headcount, holiday plans, sick leave records, daily measurement/control plan

- Responsible for PPM, DPM index and root cause analysis of any problem

- Passing on information amongst shifts and work areas

- Making sure everyone is concetrating on solving potential problems and keeping this attitude

- Operation of ISO9001

- Calibration of measuring equipments, replacement of them if needed

- College or Degree

- Previous work-related experience

- Develop Corrective Action Reports for customer and internal concerns

- Prepare prototype documentation and support prototype / pre – production builds

- Ensure supplier corrective actions are effective, documented, implemented and closed in a timely manner

- Champion scrap reduction plans for assigned programs

- Participate in Advanced Product Quality Planning

- Analyze data and provide solutions/recommendation’s for product and process improvements

- Review and approve supplier International Material Data System (IMDS)

- Coordinate 3rd party material testing as required

- Participate in quality training functions as required

- Adheres to all MAFACT requirements

- Must comply with all ISO 14001 (Environmental) and OHSAS 18001 (Health and Safety) systems and standards as it pertains to their work

- A Minimum of three years’ experience working in a Quality environment utilizing knowledge of prototype product development of products in accordance with customer requirements (AIAG)

- Working experience with Automotive Customer Specifics and AIAG requirements

- Detailed knowledge of Process Sign Off

- Follow and enforce all plant safety rules and policies

- Develop and implement Product FMEAs and Quality Control Plans for new and existing products

- Develop and implement supporting inspection instructions and criteria to maintain compliance with customer requirements

- Perform Statistical and Quality Audits as assigned

- Develop monthly quality system reports with manufacturing managers and management

- Serve as a member to the Advanced Product Quality Planning Team

- Review quality and statistical data for compliance the customer requirements; coordinate corrective and preventive actions when required

- Assist in the continuous improvement process and recommend improvement opportunities

- Coordinate and update all required documentation on changes and/or new products

- Perform as assigned, Internal Quality Audits

- Develop and recommend improvements through performance history analysis

- Coordinate Supplier Quality Assurance and Development Activities

- Develop and direct D.O.E. activities and reporting to the appropriate departments and/or personnel

- Disposition, review and prioritize non-conformances

- In the absences for the Quality Manager, take functional responsibility for the Quality Department

- Assist in customer relations and act as customer liaison

- Recommend proposals for improving products, processes, systems, productivity and working environment

- Aware of Safety, Health and Environmental policies

- Communicate and work closely with Engineering and Manufacturing on product changes and new products along with Quality Manager and Technicians

- Works closely with Engineering and Manufacturing on Product Compliance and Acceptance

- Works closely with Manufacturing Operators for correct data collection and inspection methodology

- Work with Quality Technicians and Manufacturing as a primary resource in Problem Solving, Inspection, Acceptance Criteria, and Continuous Improvement

- Customer liaison and professional contact with the customers' Quality Assurance, Engineering, and Manufacturing

- Assist supplier in their continuing quality development and in meeting AIAG/Customer/Victor Mfg. quality requirements

- B.A or B.S. Degree in Engineering, Quality Sciences or other relevant study area

- Two (2) years minimum experience as a Quality Engineer or other Quality Position

- Ability to perform Standard to Metric conversions

- Ability to perform geometry and trigonometry

- Coordinates the Company’s problem solving activities and responds to externally and internally generated non-conformances. This includes the disposition of suspected material, analyzing non-conformances, investigating causes and initiating team meetings to implement corrective actions and to prevent non-conformances

- Work on process improvement to ensure that the Company’s quality targets are met

- Participates in quality planning / improvement activities

- Responsible for the supplier development function, with assistance from MPT, including suppliers’ PPAPs, DMNs & corrective actions and overall suppliers’ performance

- Work with Manufacturing Engineers in the plant to maintain process FMEAs

- Initiates and works on assigned Continuous Improvement Projects

- Assists the Quality Assurance Manager with day-to-day plant issues

- Visit customers and suppliers from time to time as it becomes necessary

- Any other Quality Assurance duties as assigned

- University degree or College diploma in Mechanical Engineering

- 3 years automotive quality engineering experience working in a similar capacity (Quality Assurance or Process Engineering) within a manufacturing or automotive industry

- Knowledge of measuring equipment, gauge calibration, gauge R&R studies, SPC, GD&T, and inspection processes (receiving, in-process and outgoing)

- Knowledge of APQP, PPAP, QS-9000, and customer (GM, Ford, and Chrysler) requirements

- Ability to participate and contribute in a team environment

- Earlier identification of issues through the review of early quality indicators

- Leading issues through the resolution process and validation of the solutions

- Creating, modifying and validating modifications to repair and diagnostic procedures to ensure accuracy and effectiveness

- Organizing and presenting quality data to management in Quality Review meetings

- Lead issues to resolution for Hotline identified dealer issues

- Management of Functional Quality Review presentations

- Internal fleet data recorder issue resolution

- Maintain an open issues matrix for all assigned parts and program,

- Maintain customer/supplier/sub-contractor contact (including traveling when necessary whenever necessary),

- Ensure critical and significant characteristics are properly selected and maintained,

- Ensure all company/customer procedures and policies are communicated and followed,

- Participate in training of production workers when necessary,

- Post Secondary education or Engineering designation,

- Minimum of 5 years experience as a Quality Engineer within a TIER 1 or TIER 2 QS 9000 company

- GD&T experience as well as 8D’s a must

- Completes special assignments or projects established in order to achieve “Continuous Quality improvement”

- Monitor outgoing Quality levels through various “Measurables”, (SPC, First Run Capability, Daily Defect Report)

- Responsible for conducting capability studies, collecting variable data, input of data in computer software, and able to interpret results

- Able to interface with all levels of Magna Seating Employees as well as suppliers and the customer

- Participate on QOS teams as directed and focus of continuous improvement

- Ensure that proper work-instructions exist for : Receiving Inspectors

- Responsible for doing layout inspections as required

- Must be able to conduct audits at the Suppliers location and internally as required

- Oversee completion of testing as required

- Ensure that proper gages and fixtures exist for: Receiving Inspection, ES testing, Inprocess/Final Inspection

- Supervise personnel in all aspects of the Quality Department and serves as department leader

- Schedules, conducts and maintains Layered Process Audits, TS16949 audits, ISO14001 audits and internal audits and verifies action plans are develop and completed

- Liaison with third party auditors regarding audit scheduling and general communication

- Develop/approve gauging for new programs or gage revisions to existing programs

- Train associates in SPC methods and data collection systems use

- Provide instruction and guidance to inspection personal in the use of inspection equipment and interpretation of quality instructions/standards as required

- Provide assistance and support as a member of the APQP team of Montezuma Manufacturing

- Responsible for PPAP sample submissions

- Schedule CMM and coordinate gage calibration system

- Recommend and encourage others to recommend proposals for improving products, processes, systems, productivity and work environment (Continual Improvement Process)

- Maintain a positive attitude with fellow employees and help develop this attitude throughout the company. Treat all associates with dignity and respect

- High school diploma or GED with a preference to Associate or Bachelor’s degree

- Thorough knowledge and clear understanding of the TS16949, ISO14001 and customer specific requirements through training and/or experience

- Knowledge and understanding of the Automotive Industry requirements (AIAB/Core Tools, etc.)

- Must exhibit high integrity and honesty

- Ability to effectively and appropriately present information and respond to questions from various groups

- Ability to travel and obtain a passport

- Provide Quality interface and expertise between the organization and its customers to proactively assure that their needs and expectations are understood and satisfied. This includes contract review/flow-down, the complaint management process, and the implementation of the corresponding corrective / preventive actions

- Provide support to the Supply Chain Management organization relative to the collection and analysis of Supplier Quality data as well as provide Quality interface, expertise and support to the Plant's/SBU's suppliers and partners. This includes the preparation of reports of supplier performance used to give feedback to suppliers and to the organization

- Execute the initiatives of the organization in the development, implementation and improvement of the appropriate Quality Management Systems throughout the operation, with all the documentation required. This includes providing advanced quality planning support in the development and launch of new products, processes and services

- Participate in the internal Quality System Audit program for the organization. Develop, implement and audit of inspection and test plans, standards and acceptance criteria, and procedures / work instructions. Facilitate the Investigation and elimination of causes of quality problems and follow up on corrective actions

- Develop and analyze statistical data and product / process performance to recommend and implement improvements in targeted areas of the organization. Provide support in the way of development and evaluation of process capability, process control plans, analysis of out-of-control conditions and process audits with the objective of improving process performance and capability

- Participate in all aspects of product development and launch activities throughout the organization. Efforts should primarily be targeted at the identification of customer expectations, manufacturing and test support, reliability analysis, design reviews, evaluation of test programs, material testing and inspection and management of quality costs

- Act as overall facilitator of site Quality System

- Maintain compliance to ISO 9001 standards

- Be responsible for in process Quality

- Identify process improvement opportunities

- Implement corrective actions on Customer Quality issues

- Implement corrective actions on Supplier Quality issues

- Support application of Lean Six Sigma tools to improve manufacturing processes

- Work with R & D to ensure Quality Characteristics are agreed and documented for all New Product introductions

- Good Programme management skills

- A Degree level or similar qualification in Quality , mechanical or industrial engineering

- Minimum 1 years experience in a quality role within a manufacturing environment

- Demonstrated Lean / Six Sigma / Process Excellence experience

- New Product Introduction and manufacturing process transfer experience would be a distinct advantage

- Excellent written and communication skills essential

- Provide strategic leadership in the development and implementation of project quality plans to obtain annual reduction goals in Scrap, Rework and Repair (SRR) and escapes to flight operations and DCMA discrepancies

- Improve internal and external manufacturing, assembly, inspection, and test processes to reduce and prevent defects and prevent quality escapes to our customers

- Provide quality engineering support

- Conduct technical investigations

- Lead and Coach Problem Resolution and DIVE Teams comprised of manufacturing, product and quality engineering and operations support functions

- Implement immediate risk containment measures and systemic mistake proof solutions to improve quality, cost, and delivery performance at selected suppliers

- Perform manufacturing process reviews

- Drive process certification

- Develop and deliver technical training to the inspection and operations teams

- Support the development of productivity initiatives to improve product acceptance methodology. Integrate goals that will align with process quality engineering activities

- Possess a Bachelor of Science degree in an Engineering, Engineering technology, or technical discipline

- Preferred 6-8 years, but would consider 3-6 years of work related work experience in a Supplier Quality environment with demonstrated results and a notable competency progression. Past results should include successful leadership of an Engineering or Quality team

- Experience with AIAG (Automotive Industry Action Group) derived processes, including Advance Product Quality Planning (APQP) and Production Part Approval Process (PPAP) or QS-9000 in a new product development environment is preferred

- Electronics background strongly desired

- Excellent project planning skills, problem solving ability, strong oral and written communication skills, competence in inspection techniques, and strong computer skills

- ASQ certification as an Engineer and/or Auditor, or Black Belt certification is highly desirable

- Responsible for day-to-day in-process QC audits per TMaG master auditing list ranging from incoming inspections at vendors, on-line QC workstations, final inspections, gauge/tool maintenance and calibrations as well as regular testing operations etc

- Lead/coordinate vendor QC meetings on improvement activities against on-line nonconformities. Check and follow through improvement actions

- Report/communicate immediately major QC issues found on-site during auditing for immediate actions with involving superior and concerned persons from supplier

- Document daily findings and create/update auditing report on a weekly basis, distribute to concerned persons in the TMaG engineering team

- Assist tests that conducted by TMaG engineers if needed, collect and send the data that required

- Lead TMaG QC persons on-site to fully implement TMaG China QC procedure, overlook daily operations of outgoing checks, in-process audits and quality reporting etc. Also responsible for new product training and inspection qualification

- Strong interpersonal communication skills and basic computing skills

- Good command of written English, good oral skill is preferable

- Responsible, independent, active and result-oriented

- Continually evaluate and expand test coverage based on defect trends and new customer usage patterns

- Ensure our software meets functional, robustness, performance, compatibility and security requirements

- Familiarity with debugging operating systems failures using source or assembly debuggers

- Experience with Amazon Web Services, Google Compute Engine and/or Microsoft Azure

- Subject-matter expertise in one of the following areas: Linux kernel internals, storage and file systems, networking, or packaging of operating system distribution

- Crankshafts

- Connecting rods

- Hardened shafts

- Writing failure analysis reports on field return iron for customer service and product engineers. In general, failure analysis reports require the identification of root cause for the failure along with a recommended corrective action(s)

- Resolution of quality related production problems that occur in the factory

- Validating and approving PPAPs for new parts from NPI programs, CPI issues, and new suppliers. At a minimum, the material certificate and process control plan in the PPAP will need to be reviewed. For high risk components and/or suppliers, sample parts may need to be analyzed at Lafayette to confirm material properties

- Reviewing and approving process changes for parts manufactured at Lafayette as well as at suppliers

- Develop metallurgical receiving inspection plans for components. Review of components that fail receiving inspection including assessing whether they are acceptable for use or should be rejected

- Bachelors degree in materials science or metallurgical engineering

- Good writing skills as the majority of the work for this position is communicated via formal technical reports

- Positive attitude and a sense of urgency for completing tasks

- Prior experience working in a manufacturing environment or in the quality field

- Degree with emphasis on ferrous metallurgy

- Knowledge of manufacturing and assembly procedures (machining, heat treat, assembly and inspection) especially process control

- Failure analysis experience

- 6 Sigma Black Belt experience or 6 Sigma Green Belt

- Ensure the proper processes are devloped so as to ensure the quality of the products produced match the customer requirements

- Plans, supports, and implements total quality programs utilizing customer specific requirements concerning APQP, FMEA’s Control Plans, Measurement Systems Analysis, Statistical Techniques & PPAP’s. Defines scope, plans, organizes, leads and directs technical work and departmental efforts related to quality engineering activities for new and existing programs

- Investigates and solves manufacturing-related problems in assigned area using formal problem-solving tools. Leads root cause analysis of internal and external issues

- Analyzes and develops suppliers products, ensuring customer specific & internal requirements are met while obtaining maximum productivity, reviews performance in operation and provides suggestions for improvement

- Desirable to have previous experience in IVDDs, Design Controls and/or Risk Management

- Excellent interpersonal / communication skills

- Excellent planning and organisational skills

- Communicate with customers to identify and correct quality issues

- Develop suppliers, communicate and correct quality issues when needed

- Owner of certified inspection program

- Owner of returned goods process

- Bachelor degree in Engineering or Engineering Technology

- Minimum of 3 years of quality experience

- Flexibility with location; Position will start in Toccoa, GA for up to 12 months until transition to Mapleton, IL

- Willing to travel for the first year up to 50%, then travel will drop to 10-25% as needed

- Metrology experience (CMM, Instron, suface finish/contour)

- CMM programming experience, PCDMIS

- Complete Process and Equipment Validation including DV, IQ, OQ, PQ protocol development, implementation and report completion

- Develop product specifications / drawings / quality plans in conjunction with NPD and project team

- Conduct Risk Management / FMEA / Statistical analysis

- Complete ISO 13485 / FDA and QSR internal audits per annual schedule

- Implement process control and ensure process capability is maintained and identify opportunities for process improvement

- Conduct CAPA analysis to determine root cause and complete problem resolution

- Quality Engineering Qualification is desirable

- Experience in process validation

- 2/3 years' experience in Medical Device Industry

- Ability to participate in cross functional teams

- Work with Program Managers, Program Engineers and Manufacturing staff to coordinate all PPAP activities and ensure accurate and on-time submission into customer’s systems (e.g. SQMS. B2B portal Supply Power etc.)

- Update customers on PPAP status and timing on a regular basis

- Ensure effective communication and containment of quality issues identified by customers. Travel to customer’s location may be required

- Ensure effective root cause analysis and permanent corrective actions are implemented for customer quality issues. Also ensure this information is uploaded into the appropriate customer database

- Ensure every customer complaint for your customers are responded to within the customer specified timeframe

- Effectively manage the relationship with your customer to ensure that your customers view Decostar in a positive manner

- Establish boundary samples with the customer for subjective quality issues

- Assist manufacturing departments in developing their Control Plans and Work Instructions in accordance to their PFMEAs, Process Flows, Decostar’s quality system’s procedures and customer requirements

- Participate in Decostar’s cross-functional APQP meetings to review open issues and activities which need to be resolved or acted upon

- Conduct supplier quality system surveys according to ISO/TS16949 requirements

- Assist the Supplier Quality Engineer by reviewing and approving supplier PPAPs and attend supplier run at rate trial as designated

- Participate in continuous improvement programs and activities to ensure meeting of departmental performance objectives

- Perform job duties within the guidelines of the Decostar Supplier Quality Manual and ISO/TS 16949 procedures

- Knowledge of PPAP / Submission process systems or equivalent is required

- Blue print reading and GD&T is required

- Prior internal auditing or lead auditing to TS-16949 experience is required. Exposure to multiple OEM specifications, standards and quality systems is required

- Knowledge of AIAG core tools such as FMEA, Control Plan, SPC, MSA, etc. is required

- Ability to travel within and outside of the U.S. is required

- Ability to effectively communicate with all levels of personnel is required

- Interface with Engineering and Operations to ensure transfer to Production of new products are in accordance with approved requirements

- Performs inspections (audits) of finished materials

- Provide daily direction to Quality Technicians

- Manage the disposition, flow, tracking, and failure analysis results of suspect material from production fallout and Technical Support product returns

- Facilitate Material Review Board process including final disposition of product. Recommend appropriate disposition of non-compliant materials and finished goods

- Provide tier 2 support for Technical Services by providing enhanced diagnostics abilities and trend analysis in determining failure modes (design vs. workmanship vs. handling) and in identifying root causes associated with workmanship and/or handling when so identified

- Work directly with Engineering to resolve design or manufacturability issues when/if they are found to be suspect as the failure mode

- Communicate to and resolve manufacturing quality issues with off-shore Quality Engineer assigned to the contract manufacturer to push issues ‘up stream’ before they escape the factory

- In cooperation with supply chain management originate, track, and manage supplier CARs where appropriate

- Analyze failure, corrective and preventive action to respond to customer complaints

- Facilitate testing of component, in process and finished goods including routine inspection processes, audits and 3rd part testing